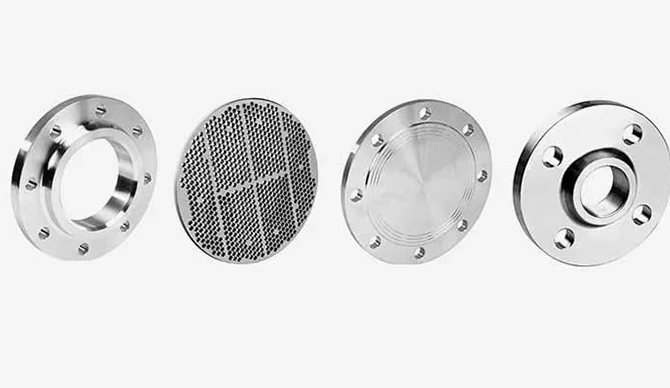

The types of stainless steel pipes are divided into: 1 stainless steel seamless steel pipe; 2 stainless steel welded pipes. According to brightness: ordinary stainless steel tube, matt stainless steel tube, bright stainless steel tube. Stainless steel pipe fittings are parts that connect pipes into pipes. Stainless steel pipe fittings can be divided into socket pipe fittings, threaded pipe fittings, flange pipe fittings and welded pipe fittings according to the connection method. Stainless steel pipe fittings are also a type of pipe fittings, because they are made of stainless steel materials, so they are called stainless steel pipe fittings. Stainless steel pipe fittings include stainless steel elbow, stainless steel tee, stainless steel cross, stainless steel reducer, stainless steel pipe cap, etc. According to the connection method, it can be divided into socket stainless steel pipe fittings, threaded stainless steel pipe fittings, flange stainless steel pipe fittings and welded stainless steel pipe fittings. Stainless steel elbows are used where pipe fittings turn; flanges are used to connect pipes to each other and parts to pipe ends. Stainless steel tee pipes are used at the confluence of three pipes; stainless steel tee pipes are used at the confluence of four pipes; stainless steel reducers are used to connect two pipes of different diameters, mainly stainless steel materials: 304, 304L, 316, 316L

Stainless steel is a kind of material with brightness close to the mirror surface, tough and cold to the touch, and is a relatively avant-garde practical material with excellent corrosion resistance, formability, compatibility and toughness and other series of characteristics, used in heavy and light industries , daily necessities industry and building decoration industries. Stainless and acid-resistant steel is referred to as stainless steel. It is composed of two parts: stainless steel and acid-resistant steel. In short, the steel that can resist atmospheric corrosion is called stainless steel, and the steel that can resist chemical medium corrosion is called acid-resistant steel. Generally speaking, steel with a chromium content of more than 12% has the characteristics of stainless steel. Stainless steel can be divided into five categories according to the microstructure after heat treatment: ferritic stainless steel, martensitic stainless steel, austenitic stainless steel, Austenitic-ferritic duplex stainless steels and precipitation hardening stainless steels.

The main advantagesCorrosion resistance. Stainless steel has a similar resistance to general corrosion as the unstable Nichrome 304. Prolonged heating in the temperature range of chromium carbide degrees may affect Alloys 321 and 347 in harsh corrosive media. Mainly used in high temperature applications, which require strong resistance to sensitization of the material to prevent intergranular corrosion at lower temperatures.

High temperature oxidation resistance. Stainless steel plates are all resistant to high temperature oxidation, however, the oxidation rate will be affected by inherent factors such as exposure environment and product form.

Physical properties. The overall heat transfer coefficient of a metal depends on other factors besides the thermal conductivity of the metal. In most cases, the heat dissipation coefficient of the film, the scale and the surface condition of the metal. Stainless steel keeps surfaces clean, so it conducts heat better than other metals with higher thermal conductivity.

Piping Material Selection Guide

Piping Material Selection Guide

The corrosion resistance of stainless steel varies with the chemical composition of the steel itself, the intergranular structure, the conditions of use and the type of environmental media. Not any kind of stainless steel, corrosion-resistant and rust-free in any environment. There is a layer of chromium-rich oxide film (protective film) on the surface of stainless steel to prevent the infiltration and oxidation of oxygen atoms, so as to obtain the ability to resist rust. Once for some reason, this film is continuously damaged, oxygen atoms in the air or liquid will continue to infiltrate or iron atoms in the metal will continue to separate out, forming loose iron oxide, and the metal surface will be continuously corroded.

Applications of Steel Piping Material

Applications of Steel Piping Material

The use of stainless steel is more and more extensive from eating tableware to aerospace, and battlefield weapons. Steel piping materials are inseparable from stainless steel, and stainless steel in stainless steel pipe in our life is more widely used, whether it is a military or civilian field, are indispensable, the following list of common application areas of stainless steel pipe.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.