The socket fitting is mainly a high-pressure elbow pipe accessory formed by forging round steel or steel ingots into blanks and then processed by a lathe. Its connection form is socket welding (Socket Welding SW), where the steel pipe is inserted into the socket hole for welding. The common product categories of socket fittings include: socket cap, socket 45 ° elbow, socket 90 ° elbow, socket equal diameter four-way, socket equal diameter four-way, socket equal diameter three-way, socket different diameter three-way, socket pipe clamp, socket movable joint, etc. Screw fittings refer to threaded fittings made of materials such as stainless steel, alloy steel, carbon steel, etc., suitable for connecting various pipelines. The types of threaded pipe fittings can be subdivided into more than ten types, covering various forms such as straight connections and curved connections, including threaded elbows, threaded tees, threaded pipe clamps, threaded pipe caps, threaded unions, threaded short joints, reducing short joints, hexagonal external threads, threaded pipe plugs, and threaded cores. The use of socket fittings is mainly suitable for high-pressure pipelines that require high pressure, equipment with precise size requirements, and various other high-pressure fields such as petrochemicals, medicine and health, power, aerospace, fire protection, metallurgy, shipbuilding, gas, nuclear power, and environmental protection.

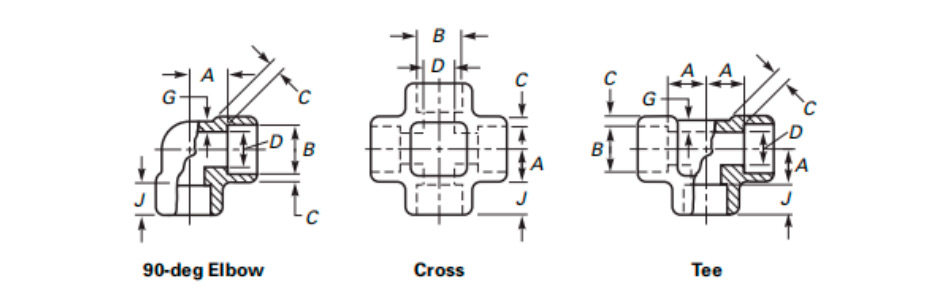

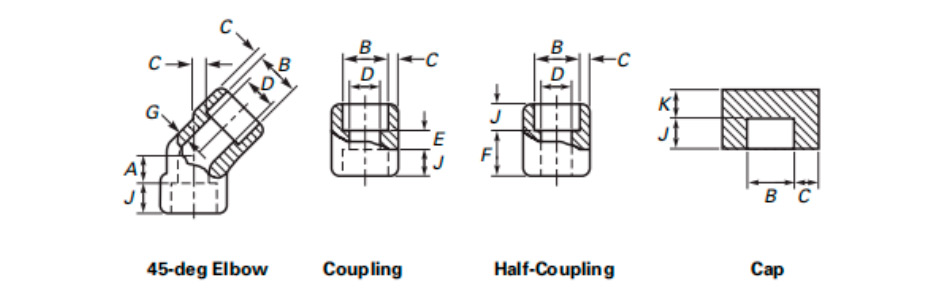

| Nominal Pipe Size | Socket Bore Diameter, B [Note(1)] | Bore Diameter of Fittings, D [Note(1)] | Socket Wall Thickness, C [Note(2)] | Body Wall, G | MIn. Depth of Socket, J | Center-to-Bottom of Socket, A | Laying Lengths | Tolerances, ± | End Wall Thickness, Kmin | |||||||||||||||||||

| Class Designation | Class Designation | Class Designation | 90-deg Elbows, Tees, and Crosses | 45-deg Elbows | Class Designation | |||||||||||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Class Designation | Couplings, E | Half Couplings, F | A | E | F | 3000 | 6000 | 9000 | ||||||||||||||

| 3000 | 6000 | 9000 | Avg. | Min. | Avg. | Min. | Avg. | Min. | Min. | Min. | Min. | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||||||

| 1/8 | 11.2 | 7.6 | 4.8 | ... | 3.18 | 3.18 | 3.96 | 3.43 | ... | ... | 2.41 | 3.15 | ... | 9.5 | 11.0 | 11.0 | ... | 8.0 | 80.0 | ... | 6.5 | 16.0 | 1.0 | 1.5 | 1.0 | 4.8 | 6.4 | ... |

| 10.8 | 6.1 | 3.2 | ... | |||||||||||||||||||||||||

| 1/4 | 14.6 | 10.0 | 7.1 | ... | 3.78 | 3.30 | 4.60 | 4.01 | ... | ... | 3.02 | 3.68 | ... | 9.5 | 11.0 | 13.5 | ... | 8.0 | 80.0 | ... | 6.5 | 16.0 | 1.0 | 1.5 | 1.0 | 4.8 | 6.4 | ... |

| 14.2 | 8.5 | 5.6 | ... | |||||||||||||||||||||||||

| 3/8 | 18.0 | 13.3 | 9.9 | ... | 4.01 | 3.50 | 5.03 | 4.37 | ... | ... | 3.20 | 4.01 | ... | 9.5 | 13.5 | 15.5 | ... | 8.0 | 11.0 | ... | 6.5 | 17.5 | 1.5 | 3.0 | 1.5 | 4.8 | 6.4 | ... |

| 17.6 | 11.8 | 8.4 | ... | |||||||||||||||||||||||||

| 1/2 | 22.2 | 16.6 | 12.5 | 7.2 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19.0 | 25.5 | 11.0 | 12.5 | 15.5 | 9.5 | 22.5 | 1.5 | 3.0 | 1.5 | 6.4 | 7.9 | 11.2 |

| 21.8 | 15.0 | 11.0 | 5.6 | |||||||||||||||||||||||||

| 3/4 | 27.6 | 21.7 | 16.3 | 11.8 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19.0 | 22.5 | 28.5 | 13.0 | 14.0 | 19.0 | 9.5 | 24.0 | 1.5 | 3.0 | 1.5 | 6.4 | 7.9 | 12.7 |

| 27.2 | 20.2 | 14.8 | 10.3 | |||||||||||||||||||||||||

| 1 | 34.3 | 27.4 | 21.5 | 16.0 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 | 12.5 | 28.5 | 2.0 | 4.0 | 2.0 | 9.6 | 11.2 | 14.2 |

| 33.9 | 25.9 | 19.9 | 14.4 | |||||||||||||||||||||||||

| 1¼ | 43.1 | 35.8 | 30.2 | 23.5 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 | 12.5 | 30.0 | 2.0 | 4.0 | 2.0 | 9.6 | 11.2 | 14.2 |

| 42.7 | 34.3 | 28.7 | 22.0 | |||||||||||||||||||||||||

| 1½ | 49.2 | 41.6 | 34.7 | 28.7 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 | 12.5 | 32.0 | 2.0 | 4.0 | 2.0 | 11.2 | 12.7 | 15.7 |

| 48.8 | 40.1 | 33.2 | 27.2 | |||||||||||||||||||||||||

| 2 | 61.7 | 53.3 | 43.6 | 38.9 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 | 19.0 | 41.0 | 2.0 | 4.0 | 2.0 | 12.7 | 15.7 | 19.0 |

| 61.2 | 51.7 | 42.1 | 37.4 | |||||||||||||||||||||||||

| 2½ | 74.4 | 64.2 | ... | ... | 8.76 | 7.67 | ... | ... | ... | ... | 7.01 | ... | ... | 16.0 | 41.0 | ... | ... | 28.5 | ... | ... | 19.0 | 43.0 | 2.5 | 5.0 | 2.5 | 15.7 | 19.0 | ... |

| 73.9 | 61.2 | ... | ... | |||||||||||||||||||||||||

| 3 | 90.3 | 79.4 | ... | ... | 9.52 | 8.30 | ... | ... | ... | ... | 7.62 | ... | ... | 16.0 | 57.0 | ... | ... | 32.0 | ... | ... | 19.0 | 44.5 | 2.5 | 5.0 | 2.5 | 19.0 | 22.4 | ... |

| 89.8 | 76.4 | ... | ... | |||||||||||||||||||||||||

| 4 | 115.7 | 103.8 | ... | ... | 10.69 | 9.35 | ... | ... | ... | ... | 8.56 | ... | ... | 19.0 | 66.5 | ... | ... | 41.0 | ... | ... | 19.0 | 48.0 | 2.5 | 5.0 | 2.5 | 22.4 | 28.4 | ... |

GENERAL NOTE: Dimensions are in millimeters.

NOTES:

(1) Upper and lower values for each size are the respective maximum and minimum dimensions.

(2) Average of socket wall thickness around periphery shall be no less than. listed values. The minimum values are permitted in localized areas.

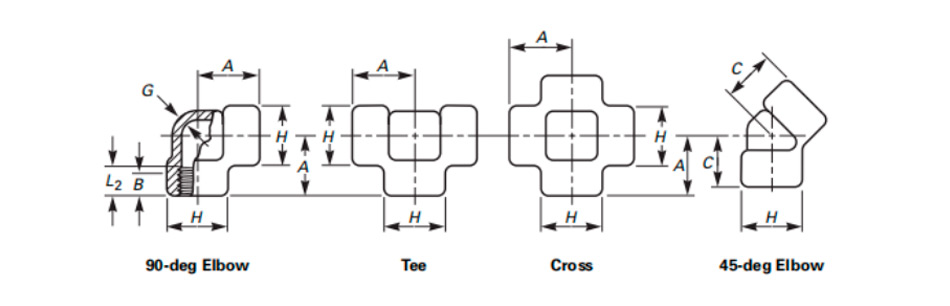

Nominal Pipe Size | Center-to-End Elbows, Tees, and Crosses, A | Center-to-End 45-deg Elbow, C | Outside Diameter of Band, H | Minimum Wall Thickness, G | Min. Length of Thread [Note(1)] | |||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | B | L₂ | |

| 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 1/2 | 28 | 33 | 38 | 22 | 25 | 33 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 1¼ | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 1½ | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 2½ | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

GENERAL NOTE: Dimensions are in millimeters.

NOTE:

(1) Dimension B is minimum length of perfect thread. The length of useful thread (B plus threads with fully fomed roots and flat crests) shall not be less than L₂ (effective length of external thread) required by American National Standard for Pipe Threads (ASME B1.20.1; see para. 6.3).

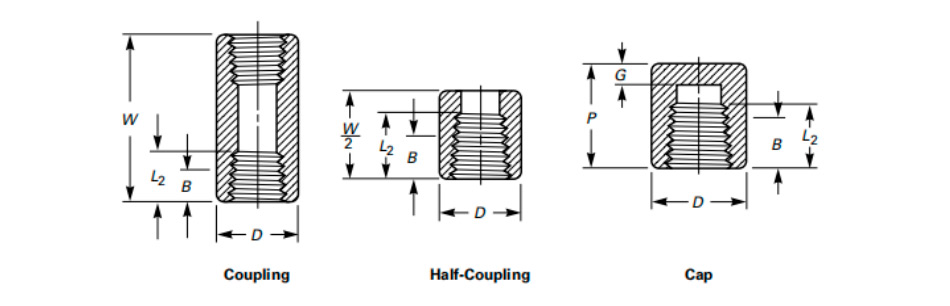

Nominal Pipe Size | End-to-End Couplings, W | End-to-End Caps, P | Outside Diameter, D | Minimum End Wall Thickness, G | Minimum Length of Thread [Note(1)] | ||||

| 3000 and 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | B | L₂ | |

| 1/8 | 32 | 19 | ... | 16 | 22 | 4.8 | ... | 6.4 | 6.7 |

| 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 1¼ | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 1½ | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 2½ | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

GENERAL NOTES:

(a) Dimensions are in millimeters.

(b) Class 2000 and NPS 1/8 Class 6000 couplings, half couplings, and caps are not included in this Standard.

(c) The wall thickness away from the threaded ends shall meet the minimum wall thickness requirements of Table 2 for the appropriate NPS and Class Designation fitting.

NOTE:

(1) Dimension B is minimum length of perfect thread. The length of useful thread(B plus thread with fully formed roots and flat crests) shall not be less than L₂ (effective length of external thread) required by American National Standard for Pipe Threads (ASME B1.20.1; see para. 6.3).

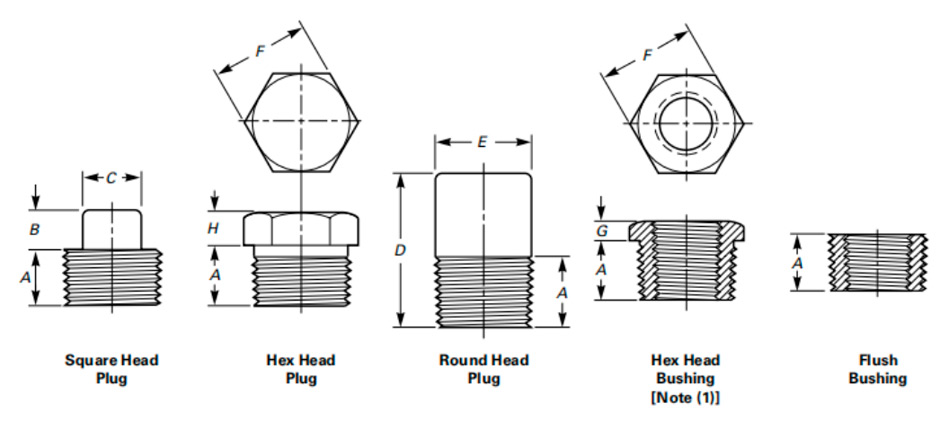

Nominal Pipe Size | Minimum Length, A | Square Head Plugs | Round Head Plugs | Hex Plugs and Bushings | ||||

Minimum Square Height, B | Minimum Width Flats, C | Nominal Head Diameter, E | Minimum Length, D | Nominal Width Flats, E | Minimum Hex Height | |||

| Bushing, G | Plug, H | |||||||

| 1/8 | 10 | 6 | 7 | 10 | 35 | 11 | ... | 6 |

| 1/4 | 11 | 6 | 10 | 14 | 41 | 16 | 3 | 6 |

| 3/8 | 13 | 8 | 11 | 18 | 41 | 18 | 4 | 8 |

| 1/2 | 14 | 10 | 14 | 21 | 44 | 22 | 5 | 8 |

| 3/4 | 16 | 11 | 16 | 27 | 44 | 27 | 6 | 10 |

| 1 | 19 | 13 | 21 | 33 | 51 | 36 | 6 | 10 |

| 1¼ | 21 | 14 | 24 | 43 | 51 | 46 | 7 | 14 |

| 1½ | 21 | 16 | 28 | 48 | 51 | 50 | 8 | 16 |

| 2 | 22 | 18 | 32 | 60 | 64 | 65 | 9 | 18 |

| 2½ | 27 | 19 | 36 | 73 | 70 | 75 | 10 | 19 |

| 3 | 28 | 21 | 41 | 89 | 70 | 90 | 10 | 21 |

| 4 | 32 | 25 | 65 | 114 | 76 | 115 | 13 | 25 |

GENERAL NOTE: Dimensions are in millimeters.

NOTE:

(1) Cautionary Note Regarding Hex Bushings: Hex head bushings of one-size reduction should not be used in services where they might be subject to hamful loads and forces other than internal pressures.

KIDY is a service-oriented enterprise that provides production and processing of seamless pipes, welded pipes, butt welded pipe fittings, high-pressure forged pipe fittings, flanges and other pipeline materials. The product design materials are carbon steel, stainless steel, alloy steel, etc., and we provide you with the services you need, including transportation, inventory, quality control, etc. We use high-quality products and professional services to reassure customers. We also provide customized manufacturing and prefabricated pipes, such as flange pipes, flange elbows, etc. Non standard parts can be customized according to drawings and samples.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.