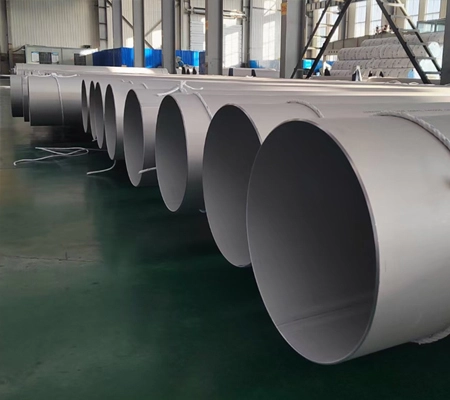

Austenitic stainless steel fluid welded pipe adopts cold processing technology, automatic welding, specification: 12-3000mm, wall thickness: 1.24-30.96mm, acid washed surface; Suitable for liquid and particle conveying pipelines, such as chemical, boiler, power, heat exchanger, condenser, food and other fields.

| TABLE 1 Chemical Requirements | |||||||||||||||||||

| Gade | UNS Desig- nationA | Composition, % | |||||||||||||||||

| Carbon | Manga-nese | Phos-phorus | Sullur | Silicon | Chrom- ium | Nickel | Molyb-denum | Tita- nium | Colum- bium | Tanta- lum. max | Nitro-genC | Vana-dium | Copper | Cerium | Boron | Alum-inum | Other | ||

| … | S20400 | 0.030 | 7.0-9.0 | 0.045 | 0.030 | 1.00 | 15.0-17.0 | 1.50-3.00 | … | … | … | … | 0.15-0.30 | … | … | … | … | … | … |

| TPXM-19 | S20910 | 0.060 | 4.0-6.0 | 0.045 | 0.030 | 1.00 | 20.5-23.5 | 11.5-13.5 | 1.50-3.00 | … | 0.10-0.30 | … | 0.20-0.40 | 0.10-0.30 | … | … | … | … | … |

| TPXM-10 | S21900 | 0.080 | 8.0-10.0 | 0.045 | 0.030 | 1.00 | 19.0-21.5 | 5.5-7.5 | … | … | … | … | 0.15-0.40 | … | … | … | … | … | … |

| TPXM-11 | S21904 | 0.040 | 8.0-10.0 | 0.045 | 0.030 | 1.00 | 19.0-21.5 | 5.5-7.5 | … | … | … | … | 0.15-0.40 | … | … | … | … | … | … |

| TPXM-29 | S24000 | 0.080 | 11,5-14.5 | 0.060 | 0.030 | 1.00 | 17.0-19.0 | 2.3-3.7 | … | … | … | … | 0.20-0.40 | … | … | … | … | … | … |

| TP201 | S20100 | 0.150 | 5.5-7.5 | 0.060 | 0.030 | 1.00 | 16.0-18.0 | 3.5-5.5 | … | … | … | … | 0.25 | … | … | … | … | … | … |

| TP201N | S20153 | 0.030 | 6.4-7.5 | 0.045 | 0.015 | 0.75 | 16.0-17.5 | 4.0-5.0 | … | … | … | … | 0.10-0.25 | … | 1.00 | … | … | … | … |

| TP304 | S30400 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | … | … | … | … | … | … | … | … | … | … | … |

| TP304L | S30403 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-13.0 | … | … | … | … | … | … | … | … | … | … | … |

| TP304H | S30409 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | … | … | … | … | … | … | … | … | … | … | … |

| … | S30415 | 0.04-0.06 | 0.80 | 0.045 | 0.030 | 1.00-2.00 | 18.0-19.0 | 9.0-10.0 | … | … | … | … | 0.12-0.18 | … | … | 0.03-0.08 | … | … | … |

| TP304N | S30451 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-18.0 | … | … | … | … | 0.10-0.16 | … | … | … | … | … | … |

| TP304LN | S30453 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | … | … | … | … | 0,10-0.16 | … | … | … | … | … | … |

| … | S30600 | 0.018 | 2.00 | 0.020 | 0.020 | 3.7-4.3 | 17.0-18.5 | 14.0-15.5 | 0.20 | … | … | … | … | … | 0.50 max | … | … | … | … |

| … | S30615 | 0.16-0.24 | 2.00 | 0.030 | 0.030 | 3.2-4.0 | 17.0-19.5 | 13.5-16.0 | … | … | … | … | … | … | … | … | 0.80-1.50 | … | |

| … | S30815 | 0.05-0.10 | 0.80 | 0.040 | 0.030 | 1.40-2.00 | 20.0-22.0 | 10.0-12.0 | … | … | … | … | 0.14-0.20 | … | … | 0.03-0.08 | … | … | … |

| TP309S | S30908 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-15.0 | 0.75 | … | … | … | … | … | … | … | … | … | … |

| TP309H | S30909 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-15.0 | … | … | … | … | … | … | … | … | … | … | … |

| TP309Cb | S30940 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-16.0 | 0.75 | … | 10xC min, 1.10 max | … | … | … | … | … | … | … | … |

| TP309HCb | S30941 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-16.0 | 0.75 | … | 10xC min, 1.10 max | … | … | … | … | … | … | … | … |

| S31002 | 0.015 | 2.00 | 0.020 | 0.015 | 0.15 | 24.0-26.0 | 19.0-22.0 | 0.10 | … | … | … | 0.10 | … | … | … | … | … | … | |

| TP310S | S31008 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0-26.0 | 19.0-22.0 | 0.75 | … | … | … | … | … | … | … | … | … | … |

| TP310H | S31009 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0-26.0 | 19.0-22.0 | … | … | … | … | … | … | … | … | … | … | … |

| S531035 | 0.04-0.10 | 0.60 | 0.030 | 0.015 | 0.40 | 215-23.5 | 23.5-26.5 | … | … | 0.30-0.60 | … | 0.15-0.30 | … | 2.0-3.5 | … | 0.002-0.008 | … | W 2.0-4.0 Co 1.0-2.0 | |

| TP310Cb | S31040 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0-26.0 | 19.0-22.0 | 0.75 | … | 10xC min, 1.10 max | … | … | … | … | … | … | … | … |

| TP310HCb | S31041 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min, 1.10 max | … | … | … | … | … | … | … | … | |

| … | S31050 | 0.025 | 2.00 | 0.020 | 0.015 | 4.00 | 24.0-26.0 | 20.5-23.5 | 1.6-2.6 | … | … | … | 0.09-0.15 | … | … | … | … | … | … |

| … | S31254 | 0.020 | 1.00 | 0.030 | 0.010 | 0.80 | 19.5-20.5 | 17.5-18.5 | 6.0-6.5 | … | … | … | 0.18-0.22 | … | 0.50-1.00 | … | … | … | … |

| S31272 | 0.08-012 | 1.5-2.00 | 0.030 | 0.015 | 0.25-0.75 | 14.0-16.0 | 14.0-16.0 | 1.00-1.4 | 0.30-0.60 | … | … | … | … | … | … | 0.004-0.008 | … | … | |

| S31277 | 0.020 | 3.00 | 0.030 | 0.010 | 0.50 | 20.5-23.0 | 26.0-28.0 | 6.5-8.0 | … | … | … | 0.30-0.40 | … | 0.50-1.50 | … | … | … | … | |

| TP316 | S31600 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11,0-14.0E | 2.00-3.00 | … | … | … | … | … | … | … | … | … | … |

| TP316L | S31603 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | … | … | … | … | … | … | … | … | … | … |

| TP316H | S31609 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11,0-14.0E | 2.00-3.00 | … | … | … | … | … | … | … | … | … | … |

| TP316T | S31635 | 0.080 | 2.00 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 5x (C+N)-0.70 | … | … | 0.10 | … | … | … | … | … | … |

| TP316N | S31651 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11,0-14.0E | 2.00-3.00 | … | … | … | 0.10-0.16 | … | … | … | … | … | … |

| TP316LN | S31653 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11,0-14.0E | 2.00-3.00 | … | … | … | 0.10-0.16 | … | … | … | … | … | … |

| TP317 | S31700 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | … | … | … | … | … | … | … | … | … | … |

| TP317L | S31703 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | … | … | … | … | … | … | … | … | … | … |

| … | S31725 | 0.030 | 2.00 | 0.040F | 0.030 | 1.00 | 18.0-20.0 | 13.5-17.5 | 4.0-5.0 | … | … | … | 0.10 | … | 0.75 | … | … | … | … |

| … | S31726 | 0.030 | 2.00 | 0.040F | 0.030 | 1.00 | 17.0-20.0 | 14.5-17.5 | 4.0-5.0 | … | … | … | 0.10-0.20 | … | 0.75 | … | … | … | … |

| … | S31727 | 0.030 | 1.00 | 0.030 | 0.030 | 1.00 | 17.5-19.0 | 14.5-16.5 | 3.8-4.5 | … | … | … | 0.15-0.21 | … | 28-4.0 | … | … | … | … |

| … | S32053 | 0.030 | 1.00 | 0.030 | 0.010 | 1.00 | 22.0-24.0 | 24.0-26.0 | 5.0-6.0 | … | … | … | 0,17-0.22 | … | … | … | … | … | … |

| TP321 | S32100 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | … | a | … | … | 0.10 | … | … | … | … | … | … |

| TP321H | S32109 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | … | H | … | … | 0.10 | … | … | … | … | … | … |

| … | S32615 | 0.070 | 2.00 | 0.045 | 0.030 | 4.8-6.0 | 16.5-19.5 | 19.0-22.0 | 0.30-1.50 | … | … | … | … | … | 1.50-2.50 | … | … | … | … |

| … | S32654 | 0.020 | 2.0-4.0 | 0.030 | 0.005 | 0.50 | 24.0-25.0 | 21.0-23.0 | 7.0-8.0 | … | … | … | 0.45-0.55 | … | 0.30-0.60 | … | … | … | … |

| … | S33228 | 0.04-0.08 | 1.00 | 0.020 | 0.015 | 0.30 | 26.0-28.0 | 31.0-33.0 | … | … | 0.60-1.00 | … | … | … | … | 0.05-0.10 | … | 0.025 | |

| … | S34565 | 0.030 | 5.0-7.0 | 0.030 | 0.010 | 1.00 | 23.0-25.0 | 16.0-18.0 | 4.0-5.0 | … | 0.10 | … | 0.40-0.60 | … | … | … | … | … | … |

| TP347 | S34700 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-13.0 | … | … | I | … | … | … | … | … | … | … | … |

| TP347H | S34709 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-13.0 | … | … | J | … | … | … | … | … | … | … | … |

| TABLE 1 Continued | |||||||||||||||||||

| Gade | UNS Desig- nationA | Composition, %B | |||||||||||||||||

| Carbon | Manga-nese | Phos-phorus | Sullur | Silicon | Chrom- ium | Nickel | Molyb-denum | Tita- nium | Colum-bium | Tanta-lum. max | Nitro-genC | Vana-dium | Copper | Cerium | Boron | Alum-inum | Other | ||

| TP347LN | S34751 | 0.005-0.020 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-13.0 | 0.20-0.50K | … | 0.06-0.10 | … | … | … | … | … | … | ||

| TP348 | S34800 | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-13.0 | … | … | I | 0.10 | … | … | … | … | … | … | … |

| TP348H | S34809 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-13.0 | … | … | J | 0.10 | … | … | … | … | … | … | … |

| … | S35045 | 0.06-0.10 | 1.50 | … | 0.015 | 1.00 | 25.0-29.0 | 32.0-37.0 | … | 0.15-0.60 | … | … | … | … | 0.75 | … | … | 0.15-0.60 | … |

| … | S35315 | 0.04-0.08 | 2.00 | 0.040 | 0.030 | 1.20-2.00 | 24.0-26.0 | 34.0-36.0 | … | … | … | … | 0.12-0.18 | … | … | 0.03-0.08 | … | … | … |

| TPXM-15 | S38100 | 0.080 | 2.00 | 0.030 | 0.030 | 1.50-2.50 | 17.0-19.0 | 17.5-18.5 | … | … | … | … | … | … | … | … | … | … | … |

| … | S38815 | 0.030 | 2.00 | 0.040 | 0.020 | 5.5-6.5 | 13.0-15.0 | 15.0-17.0 | 0.75-1.50 | … | … | … | … | … | 0.75-1.50 | … | … | 0.30 | … |

| Alloy 20 | N08020 | 0.070 | 2.00 | 0.045 | 0.035 | 1.00 | 19.0-21.0 | 32.0-38.0 | 2.0-3.0 | … | N | N | … | 3.0-4.0 | … | … | … | … | |

| … | N08367 | 0.030 | 2.00 | 0.040 | 0.030 | 1.00 | 20.0-22.0 | 23.5-25.5 | 6.0-7.0 | … | … | … | 0.18-0.25 | … | 0.75 | … | … | … | … |

| 800 | N08800 | 0.100 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | … | … | … | … | … | … | 0.75 | … | … | 0.15-0.60 | FeL-39.5 min. |

| 800H | N08810 | 0.05-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | … | 0.15-0.60 | … | … | … | … | 0.75 | … | … | 0.15-0.60 | FeL-39.5 min. |

| … | N08811 | 0.06-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | … | 0.15-0.60M | … | … | … | … | 0.75 | … | … | 0.15-0.60M | FeL-39.5 min. |

| … | N08904 | 0.020 | 2.00 | 0.040 | 0.030 | 1.00 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | … | … | … | 0.10 | … | 1.00-2.00 | … | … | … | … |

| … | N08925 | 0.020 | 1.00 | 0.045 | 0.030 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | … | … | … | 0.10-0.20 | … | 0.80-1.50 | … | … | … | … |

| … | N08926 | 0.020 | 2.00 | 0.030 | 0.010 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | … | … | … | 0.15-0.25 | … | 0.50-1.50 | … | … | … | … |

A. New designation established in accordance with Practice E527 and SAE J1086.

B. Maximum, unles othewise iniatd Where elpsgs (.. aopar in this table, there is no rquirment and analys tor the olement need not be detemined or mported

C. The method o anaysis tor mitogn shall be a matr oi ageement betwven the puchaser and manutacurer.

D. For small dameter or thin wals or both, whe manry drawing passes are rqured a carton maimum of 0.040% is necesssy in grades. TP304Land TP316L. Small outside dame tubes are defined as those less than 0.500 in. [12.7 mm] in outside diameter and light wall tubes as those less than 0.049 in. [1.20 mm] in average wall thickness (0.044 in. [1.10 mm] in minimum wall thickness),

E. For welded TP316, TP316N, TP316LN, and TP316H pipe, the nickel range shal be 10.0-14.0%.

F. For weldled pipe, the phosphonus maximum sallb 0.045%

G. Ti5x (C+N) min, 0.70 max

N. Ti4x (C+N) min, 0.60 max

I. The columbium content shall be not less than ten times the carbon content and not more than 1.00 %.

J. The columbum content shall be not lesss than eight times the carbon comlent and not more han 10 %.

K. Grade S34751 shall have a columbum (niblum) conient of not less than 15 times. the carton conient.

L. lron shall be detemined arithmetically by difference of 100 minus the sum of the other specified elements.

M. (Al+ Ti) 0.85-1.20.

N. Columbium (Nb) + Tantalum =8 x Carbon min, 1.00 max.

KIDY is a service-oriented enterprise, with regular steel grades such as TP304/TP304L, TP321, TP316/TP316L, etc. Regular medium specifications are available in stock for long-term delivery, with a fixed length of 6 meters per piece,

Austenitic stainless steel pipe refers to stainless steel with austenitic structure at high temperature and room temperature. When the steel contains about 18% Cr, 8%~10% Ni, and about 0.1% C, it has a stable austenite structure.

Austenitic chromium nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr Ni series steel developed by increasing Cr and Ni content and adding elements such as Mo, Cu, Si, Nb, Ti, etc. on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is not possible to strengthen it through phase transformation, and can only be strengthened through cold working. For example, adding elements such as S, Ca, Se, Te, etc., will result in good machinability.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.