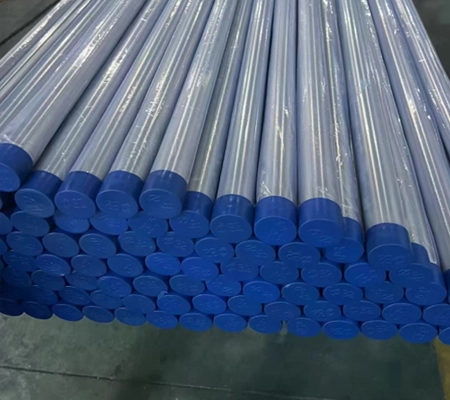

BS EN 10217-7 Stainless steel welded pipes for pressure purposes are formed by cold working process and automatic welding. The specifications are 12-1219.2mm, the wall thickness is 1.24-30.96mm, and the surface is pickled; Suitable for liquid, particle, gas conveying pipelines, such as chemical, boiler, power, food and other fields.

| Table 2- Chemical composition (cast analysis)a of austenitic corrosion resisting steels, in % by mass | ||||||||||||||

| Steel grade | C max | Si | Mn | P max | S max | N | Cr | Cu | Mo | Nb | Ni | Ti | Others | |

| Steel name | Steel number | |||||||||||||

| X2CrNi18-9 | 1.4307 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 17.5 to 19.5 | - | - | - | 8.0 to 10.0C | - | - |

| X2CrNi19-11 | 1.4306 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 18.0 to 20.0 | - | - | - | 10.0 to 12.0 | - | - |

| X2CrNiN18-10 | 1.4311 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | 0.12 to 0.22 | 17.0 to 19.5 | - | - | - | 8.5 to 11.5 | - | - |

| X5CrNi18-10 | 1.4301 | 0.070 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 17.0 to 19.5 | - | - | - | 8.0 to 10.5 | - | - |

| X6CrNTi18-10 | 1.4541 | 0.080 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | - | 17.0 to 19.0 | - | - | - | 9.0 to 12.0d | 5xC to 0.70 | - |

| X6CrNiNb18-10 | 1.4550 | 0.080 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | - | 17.0 to 19.0 | - | - | 10xC.to 1.00 | 9.0 to 12.0d | - | - |

| X1CrNi25-21 | 1.4335 | 0.020 | ≤0.25 | ≤2.00 | 0.025 | 0.010 | ≤0.10 | 24.0 to 26.0 | - | ≤0.20 | - | 20.0 to 22.0 | - | - |

| X2CrNiMo17-12-2 | 1.4404 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 16.5 to 18.5 | - | 2.0 to 2.5 | - | 10.0 to 13.0e | - | - |

| X5CrNiMo17.12-2 | 1.4401 | 0.070 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 16.5 to 18.5 | - | 2.0 to 2.5 | - | 10.0 to 13.0 | - | - |

| X1CrNiMoN25-22-2 | 1.4466 | 0.020 | ≤0.70 | ≤2.00 | 0.025 | 0.010 | 0.10 to 0.16 | 24.0 to 26.0 | - | 2.00 to 2.50 | - | 21.0 to 23.0 | - | - |

| X6CrNiMoTi17-12-2 | 1.4571 | 0.080 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | - | 16.5 to 18.5 | - | 2.00 to 2.50 | - | 10.5 to 13.5c | 5xC to 0.70 | - |

| X6CrNiMoNb17-12-2 | 1.4580 | 0.080 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | - | 16.5 to 18.5 | - | 2.00 to 2.50 | 10xC to 1.00 | 10.5 to 13.5 | - | - |

| X2CrNiMoN17-13-3 | 1.4429 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | 0.12to 0.22 | 16.5 to 18.5 | - | 2.50 to 3.0 | - | 11.0 to 14.0d | - | - |

| X3CrNiMo17-13-3 | 1.4436 | 0.050 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 16.5 to 18.5 | - | 2.50 to 3.0 | - | 10.5 to 13.0d | - | - |

| X2CrNiMo18-14-3 | 1.4435 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015b | ≤0.10 | 17.0 to 19.0 | - | 2.50 to 3.0 | - | 12.5 to 15.0 | - | - |

| X2CrNiMoN17-13-5 | 1.4439 | 0.030 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | 0.12 to 0.22 | 16.5 to 18.5 | - | 4.0 to 5.0 | - | 12.50 to 14.5 | - | - |

| X1NiCrMoCu31-27-4 | 1.4563 | 0.020 | ≤0.70 | ≤2.00 | 0.030 | 0.010 | ≤0.10 | 26.0 to 28.0 | 0.70 to 1.50 | 3.0 to 4.0 | - | 30.0 to 32.0 | - | - |

| X1NiCrMoCu25-20-5 | 1.4539 | 0.020 | ≤0.70 | ≤2.00 | 0.030 | 0.010 | ≤0.15 | 19.0 to 21.0 | 1.20 to 2.00 | 4.0 to 5.0 | - | 24.0 to 26.0 | - | - |

| X1CrNiMoCuN20-18-7 | 1.4547 | 0.020 | ≤0.70 | ≤1.00 | 0.030 | 0.010 | 0.18 to 0.25 | 19.5 to 20.5 | 0.50 to 1.00 | 6.0 to 7.0 | - | 17.5 to 18.5 | - | - |

| X1NiCrMoCuN25-20-7 | 1.4529 | 0.020 | ≤0.50 | ≤1.00 | 0.030 | 0.010 | 0.15 to 0.25 | 19.0 to 21.0 | 0.50 to 1.50 | 6.0 to 7.0 | - | 24.0 to 26.0 | - | - |

| X2NiCrATi32-20 | 1.4558 | 0.020 | ≤0.70 | ≤1.00 | 0.020 | 0.015 | - | 20.0 to 23.0 | - | - | - | 32.0 to 35.0 | 8X(C+N) to 0.60 | Al: 0.15 to 0.45 |

A. Elements not listed in this table shall not be intentionally added to the steel without the agreement of the purchaser except for finishing the cast. All appropriate precautions are to be taken to avoid the addition of such elements from scrap and other materials used in production which would impair mechanical properties and the suitability of the steel.

B. For products to be machined a controlled sulphur content of 0.015 % to 0.030 % is permitted by agreement provided the resistance to corrosion is still satisfied for the intended purpose. Option 3:A sulphur content of 0.015 % to 0.030 % is specified.

C. Where for special reasons. e.g hot workabiliy it is necessary to minimize the deltaferrite content, or with the aim of low permeabiliy, the maximum nickel content may be increased by 0.50%.

D. Where for special reasons. e.g hot workabiliy it is necessary to minimize the deltaferrite content, or with the aim of low permeabiliy, the maximum nickel content may be increased by 1.00%.

E. Where for special reasons. e.g hot workabiliy it is necessary to minimize the deltaferrite content, or with the aim of low permeabiliy, the maximum nickel content may be increased by 1.50%.

| Table 3- Chemical composition (cast analysis)a of austenitic creep resisting steels, in % by mass | ||||||||||||||

| Steel grade | C | Si | Mn | P max | S max | N | Cr | Cu | Mo | Nb | Ni | Ti | Others | |

| Steel name | Steel number | |||||||||||||

| X6CrNi18-10 | 1.4948 | 0.04 to 0.08 | ≤1.00 | ≤2.00 | 0.035 | 0.015 | ≤0.10 | 17.0 to 19.0 | - | - | - | 8.0 to 11.0 | - | - |

| X7CrNTi18-10 | 1.4940 | 0.04 to 0.08 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | ≤0.10 | 17.0 to 19.0 | - | - | - | 9.0 to 13.0 | 5x(C+N) to 0.80 | - |

| X7CrNiNb18-10 | 1.4912 | 0.04 to 0.10 | ≤1.00 | ≤2.00 | 0.040 | 0.015 | ≤0.10 | 17.0 to 19.0 | - | - | 10xC to 1.20 | 9.0 to 12.0 | - | - |

| X6CrNTiB18-10 | 1.4941 | 0.04 to 0.08 | ≤1.00 | ≤2.00 | 0.035 | 0.015 | - | 17.0 to 19.0 | - | - | - | 9.0 to 12.0 | 5xC to 0.80 | B; 0.001 5 to 0.005 0 |

| X6CrNiMo17-13-2 | 1.4918 | 0.04 to 0.08 | ≤0.75 | ≤2.00 | 0.035 | 0.015 | ≤0.10 | 16.0 to 18.0 | - | 2.00 to 2.50 | - | 12.0 to 14.0 | - | |

| X5NiCrAlTi31-20(+RA)b | 1.4958(+RA) | 0.04 to 0.08 | ≤0.70 | ≤1.50 | 0.015 | 0.010 | - | 19.0 to 22.0 | ≤0.50 | - | ≤0.10 | 30.0 to 32.5 | 0.20 to 0.50 | Al: 0.20 to 0.50 Al+Ti: ≤0.70 Co:≤0.5 Ni+Co = 30.0 to 32.5 |

| X8NiCrAlTi32-21 | 1.4959 | 0.05 to 0.10 | ≤0.70 | ≤1.50 | 0.015 | 0.010 | - | 19.0 to 22.0 | ≤0.50 | - | - | 30.0 to 34.0 | 0.25 to 0.65 | Al: 0.20 to 0.65 |

| X3CrNiMoBN17-13-3 | 1.4910 | ≤0.04 | ≤0.75 | ≤2.00 | 0.035 | 0.015 | 0.10 to 0.18 | 16.0 to 18.0 | - | 2.00 to 3.0 | - | 12.0 to 14.0 | - | B; 0.001 5 to 0.005 0 |

| X8CrNiNb16-13 | 1.4961 | 0.04 to 0.10 | 0.30 to 0.60 | ≤1.50 | 0.035 | 0.015 | - | 15.0 to 17.0 | - | - | 10xC to 1.20 | 12.0 to 14.0 | - | - |

| X8CrNiMoVNb16-13 | 1.4988 | 0.04 to 0.10 | 0.30 to 0.60 | ≤1.50 | 0.035 | 0.015 | 0.06 to 0.14 | 15.5 to 17.5 | - | 1.10 to 1.50 | 10xC to 1.20 | 12.5 to 14.5 | - | V; 0.60 to 0.85 |

| X8CrNiMoNb16-16 | 1.4981 | 0.04 to 0.10 | 0.30 to 0.60 | ≤1.50 | 0.035 | 0.015 | - | 15.5 to 17.5 | - | 1.60 to 2.00 | 10xC to 1.20 | 15.5 to 17.5 | - | - |

| X10CrNiMoMnNbVB15-10- 1 | 1.4982 | 0.06 to 0.15 | 0.20 to 1.00 | 5.50 to 7.00 | 0.035 | 0.015 | - | 14.0 to 16.0 | - | 0.80 to 1.20 | 0.75 to 1.25 | 9.0 to 11.0 | - | V; 0.15 to 0.40 B; 0.003to 0.009 |

A. Elements not listed in this table shall not be intentionally added to the steel without the agreement of the purchaser except for finishing the cast. All appropriate precautions are to be taken to avoid the addition of such elements from scrap and other materials used in production which would impair mechanical properties and the suitability of the steel.

B. Recrystallizing annealed condition.

C. Including Ta.

| Table4 - Chemical composition (cast analysis)a of austenitic-ferritic steels, in % by mass | ||||||||||||

| Steel grade | C max | Si | Mn | P max | S max | N | Cr | Cu | Mo | Ni | others | |

| Steel name | Steel number | |||||||||||

| X2CrNiMoN22-5-3 | 1.4462 | 0.030 | ≤1.00 | ≤2.00 | 0.035 | 0.015 | 0.10 to 0.22 | 21.0 to 23.0 | - | 2.50 to 3.5 | 4.5 to 6.5 | - |

| X2CrNiMoSi18-5-3 | 1.4424 | 0.030 | 1.40 to 2.00 | 1.20 to 2.00 | 0.035 | 0.015 | 0.05 to 0.10 | 18.0 to 19.0 | - | 2.50 to 3.0 | 4.5 to 5.2 | - |

| X2CrNiN23-4 | 1.4362 | 0.030 | ≤1.00 | ≤2.00 | 0.035 | 0.015 | 0.05 to 0.20 | 22.0 to 24.0 | 0.10 to 0.60 | 0.10 to 0.60 | 3.5 to 5.5 | - |

| X2CrNiMoN25-7-4 | 1.4410 | 0.030 | ≤1.00 | ≤2.00 | 0.035 | 0.015 | 0.20 to 0.35 | 24.0 to 26.0 | - | 3.00 to 4.5 | 6.0 to 8.0 | - |

| X2CrNiMoCuN25-6-3 | 1.4507 | 0.030 | ≤0.70 | ≤2.00 | 0.035 | 0.015 | 0.15 to 0.30 | 24.0 to 26.0 | 1.00 to 2.50 | 2.70 to 4.0 | 5.5 to 7.5 | - |

| X2CrNiMoCuWN25-7-4 | 1.4501 | 0.030 | ≤1.00 | ≤1.00 | 0.035 | 0.015 | 0.20 to 0.30 | 24.0 to 26.0 | 0.50 to 1.00 | 3.00 to 4.0 | 6.0 to 8.0 | W: 0.50 to 1.00 |

A. Elements not listed in this table shall not be intentionally added to the steel without the agreement of the purchaser except for finishing the cast. All appropriate precautions are to be taken to avoid the addition of such elements from scrap and other materials used in production which would impair mechanical properties and the suitability of the steel.

KIDY is a service-oriented enterprise, with regular steel grades and specifications available for long-term delivery of raw materials. The thickness grade and length of a single piece can be customized according to requirements, and special requirements can be made to order.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.