In pipeline systems, welded pipe fittings are pressure pipeline components used to change the direction or diameter of pipelines, branch pipelines, and achieve special connection functions in production equipment such as petrochemical and power plants. They are fittings connected to pipes through welding, especially suitable for long pipelines and pipelines that do not require frequent disassembly. Due to changes in the flow direction and flow area of the medium at its installation location, its internal and external stress situations are relatively complex. Therefore, the quality level of the pipe fittings directly affects the safe and stable operation of the entire pipeline system. They have multiple product types to choose from, such as 90 ° elbows, 45 ° elbows, tees, tees, caps, concentric reducers, eccentric reducers, and flanged short joints. Product standard JIS B2313 \ JIS B2311 \ JIS B2313. Welded pipe fittings are mainly suitable for high-pressure pipelines that require high pressure in petrochemical, pharmaceutical and health, power, aerospace, fire protection, metallurgy, shipbuilding, gas, nuclear power, and environmental protection, as well as equipment with precise size requirements and various other high-pressure fields.

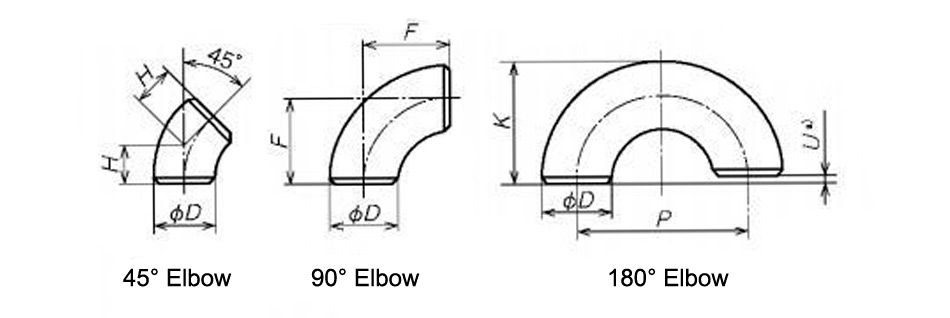

Unit: mm

| Diameter | Outer Diameter D | Distance from Center to End Face | Distance from Center to Center | Distance from Back to End Face | |||||

| 45° Elbow H | 90° Elbow F | 180° Elbow P | 180° Elbow K | ||||||

| A | B | Long | Long | Short | Long | Short | Long | Short | |

| 15 | 1/2 | 21.7 | 15.8 | 38.1 | - | 76.2 | - | 49.0 | - |

| 20 | 3/4 | 27.2 | 15.8 | 38.1 | - | 76.2 | - | 51.7 | - |

| 25 | 1 | 34.0 | 15.8 | 38.1 | 25.4 | 76.2 | 50.8 | 55.1 | 42.4 |

| 32 | 1¼ | 42.7 | 19.7 | 47.6 | 31.8 | 95.2 | 63.6 | 69.0 | 53.2 |

| 40 | 1½ | 48.6 | 23.7 | 57.2 | 38.1 | 114.4 | 76.2 | 81.5 | 62.4 |

| 50 | 2 | 60.5 | 31.6 | 76.2 | 50.8 | 152.4 | 101.6 | 106.5 | 81.1 |

| 65 | 2% | 76.3 | 39.5 | 95.3 | 63.5 | 190.6 | 127.0 | 133.5 | 101.7 |

| 80 | 3 | 89.1 | 47.3 | 114.3 | 76.2 | 228.6 | 152.4 | 158.9 | 120.8 |

| 90 | 3½ | 101.6 | 55.3 | 133.4 | 88.9 | 266.8 | 177.8 | 184.2 | 139.7 |

| 100 | 4 | 114.3 | 63.1 | 152.4 | 101.6 | 304.8 | 203.2 | 209.6 | 158.8 |

| 125 | 5 | 139.8 | 78.9 | 190.5 | 127.0 | 381.0 | 254.0 | 260.4 | 196.9 |

| 150 | 6 | 165.2 | 94.7 | 228.6 | 152.4 | 457.2 | 304.8 | 311.2 | 235.0 |

| 200 | 8 | 216.3 | 126.3 | 304.8 | 203.2 | 609.6 | 406.4 | 413.0 | 311.4 |

| 250 | 10 | 267.4 | 157.8 | 381.0 | 254.0 | 762.0 | 508.0 | 514.7 | 387.7 |

| 300 | 12 | 318.5 | 189.4 | 457.2 | 304.8 | 914.4 | 609.6 | 616.5 | 464.1 |

| 350 | 14 | 355.6 | 220.9 | 533.4 | 355.6 | 1066.8 | 711.2 | 711.2 | 533.4 |

| 400 | 16 | 406.4 | 252.5 | 609.6 | 406.4 | 1219.2 | 812.8 | 812.8 | 609.6 |

| 450 | 18 | 457.2 | 284.1 | 685.8 | 457.2 | - | - | - | - |

| 500 | 20 | 508.0 | 315.6 | 762.0 | 508.0 | - | - | - | - |

| 550 | 22 | 558.8 | 347.2 | 838.2 | 558.8 | - | - | - | - |

| 600 | 24 | 609.6 | 378.7 | 914.4 | 609.6 | - | - | - | - |

| 650 | 26 | 660.4 | 410.3 | 990.6 | 660.4 | - | - | - | - |

| 700 | 28 | 711.2 | 441.9 | 1066.8 | 711.2 | - | - | - | - |

| 750 | 30 | 762.0 | 473.4 | 1143.0 | 762.0 | - | - | - | - |

| 800 | 32 | 812.8 | 505.0 | 1219.2 | 812.8 | - | - | - | - |

| 850 | 34 | 863.6 | 536.6 | 1295.4 | 863.6 | - | - | - | - |

| 900 | 36 | 914.4 | 568.1 | 1371.6 | 914.4 | - | - | - | - |

| 950 | 38 | 965.2 | 599.7 | 1447.8 | 965.2 | - | - | - | - |

| 1000 | 40 | 1016.0 | 631.2 | 1524.0 | 1016.0 | - | - | - | - |

| 1050 | 42 | 1066.8 | 662.8 | 1600.2 | 1066.8 | - | - | - | - |

| 1100 | 44 | 1117.6 | 694.4 | 1676.4 | 1117.6 | - | - | - | - |

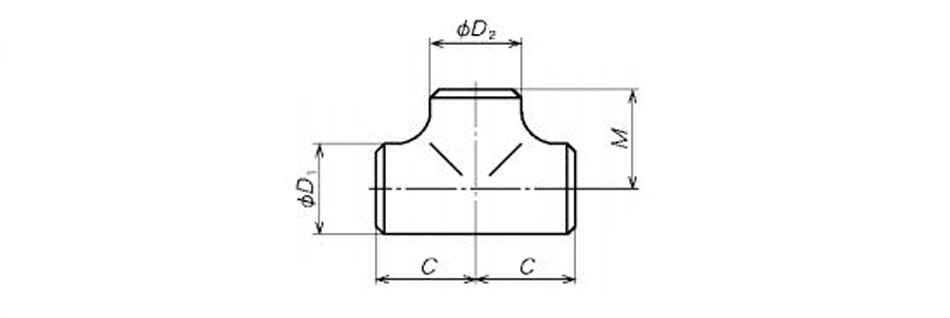

Unit: mm

| Diameter | External Diameter | Distance from Center to End Face | |||

| A | B | D1 | D2 | C | Ma) |

| 15 | 1/2 | 21.7 | 21.7 | 25.4 | 25.4 |

| 20 | 3/4 | 27.2 | 27.2 | 28.6 | 28.6 |

| 25 | 1 | 34.0 | 34.0 | 38.1 | 38.1 |

| 32 | 1¼ | 42.7 | 42.7 | 47.6 | 47.6 |

| 40 | 1½ | 48.6 | 48.6 | 57.2 | 57.2 |

| 50 | 2 | 60.5 | 60.5 | 63.5 | 63.5 |

| 65 | 2½ | 76.3 | 76.3 | 76.2 | 76,2 |

| 80 | 3 | 89.1 | 89.1 | 85.7 | 85.7 |

| 90 | 3½ | 101.6 | 101.6 | 95.3 | 95.3 |

| 100 | 4 | 114.3 | 114.3 | 104.8 | 104.8 |

| 125 | 5 | 139.8 | 139.8 | 123.8 | 123.8 |

| 150 | 6 | 165.2 | 165.2 | 142.9 | 142.9 |

| 200 | 8 | 216.3 | 216.3 | 177.8 | 177.8 |

| 250 | 10 | 267.4 | 267.4 | 215.9 | 215.9 |

| 300 | 12 | 318.5 | 318.5 | 254.0 | 254.0 |

| 350 | 14 | 355.6 | 355.6 | 279.4 | 279.4 |

| 400 | 16 | 406.4 | 406.4 | 304.8 | 304.8 |

| 450 | 18 | 457.2 | 457.2 | 342.9 | 342.9 |

| 500 | 20 | 508.0 | 508.0 | 381.0 | 381.0 |

| 550 | 22 | 558.8 | 558.8 | 419.1 | 419.1 |

| 600 | 24 | 609.6 | 609.6 | 431.8 | 431.8 |

| 650 | 26 | 660.4 | 660.4 | 495.3 | 495.3 |

| 700 | 28 | 711.2 | 711.2 | 520.7 | 520.7 |

| 750 | 30 | 762.0 | 762.0 | 558.8 | 558.8 |

| 800 | 32 | 812.8 | 812.8 | 596.9 | 596.9 |

| 850 | 34 | 863.6 | 863.6 | 635.0 | 635.0 |

| 900 | 36 | 914.4 | 914.4 | 673.1 | 673.1 |

| 950 | 38 | 965.2 | 965.2 | 711.2 | 711.2 |

| 1 000 | 40 | 1 016.0 | 1 016.0 | 749.3 | 749.3 |

| 1 050 | 42 | 1 066.8 | 1 066.8 | 762.0 | 711.2 |

| 1 100 | 44 | 1 117.6 | 1 117.6 | 812.8 | 762.0 |

| 1 150 | 46 | 1 168.4 | 1 168.4 | 850.9 | 800.1 |

| 1 200 | 48 | 1 219.2 | 1 219.2 | 889.0 | 838.2 |

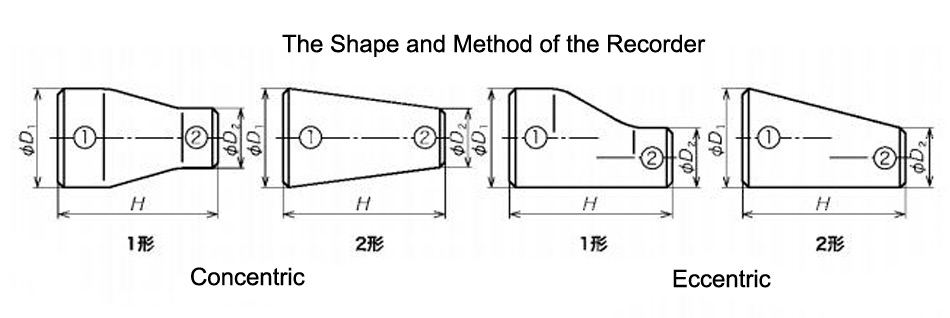

Unit: mm

| Diameter ① × ② | External Diameter | Distance from End Face to End Face H | ||

| A | B | D1 | D2 | |

| 20 × 15 | 3/4 × 1/2 | 27.2 | 21.7 | 38.1 |

| 25 × 20 | 1 × 3/4 | 34.0 | 27.2 | 50.8 |

| 25 × 15 | 1 × 1/2 | 34.0 | 21.7 | 50.8 |

| 32 × 25 | 1¼ × 1 | 42.7 | 34.0 | 50.8 |

| 32 × 20 | 1¼ × 3/4 | 42.7 | 27.2 | 50.8 |

| 32 × 15 | 1¼ × 1/2 | 42.7 | 21.7 | 50.8 |

| 40 × 32 | 1½ × 1¼ | 48.6 | 42.7 | 63.5 |

| 40 × 25 | 1½ × 1 | 48.6 | 34.0 | 63.5 |

| 40 × 20 | 1½ × 3/4 | 48.6 | 27.2 | 63.5 |

| 40 × 15 | 1½ × 1/2 | 48.6 | 21.7 | 63.5 |

| 50 × 40 | 2 × 1½ | 60.5 | 48.6 | 76.2 |

| 50 × 32 | 2 × 1¼ | 60.5 | 42.7 | 76.2 |

| 50 × 25 | 2 × 1 | 60.5 | 34.0 | 76.2 |

| 50 × 20 | 2 × 3/4 | 60.5 | 27.2 | 76.2 |

| 65 × 50 | 2½ × 2 | 76.3 | 60.5 | 88.9 |

| 65 × 40 | 2½ × 1½ | 76.3 | 48.6 | 88.9 |

| 65 × 32 | 2½ × 1¼ | 76.3 | 42.7 | 88.9 |

| 65 × 25 | 2½ × 1 | 76.3 | 34.0 | 88.9 |

| 80 × 65 | 3 × 2½ | 89.1 | 76.3 | 88.9 |

| 80 × 50 | 3 × 2 | 89.1 | 60.5 | 88.9 |

| 80 × 40 | 3 × 1½ | 89.1 | 48.6 | 88.9 |

| 80 × 32 | 3 × 1¼ | 89.1 | 42.7 | 88.9 |

KIDY is a service-oriented enterprise that provides fittings for changing the direction of pipelines in pipeline systems. Butt welded elbows are made by welding two steel plates. Generally, large-diameter elbows are butt welded, so in industrial applications, elbows with a diameter of 600 or above are mostly butt welded. Other commonly used elbows in fluid pipeline engineering construction include 45 ° elbows and 180 ° elbows. Our company can also customize other non-standard elbows according to engineering needs.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.