In pipeline systems, welded pipe fittings are pressure pipeline components used to change the direction or diameter of pipelines, branch pipelines, and achieve special connection functions in production equipment such as petrochemical and power plants. They are fittings connected to pipes through welding, especially suitable for long pipelines and pipelines that do not require frequent disassembly. Due to changes in the flow direction and flow area of the medium at its installation location, its internal and external stress situations are relatively complex. Therefore, the quality level of the pipe fittings directly affects the safe and stable operation of the entire pipeline system. They have multiple product types to choose from, such as 90 ° elbows, 45 ° elbows, tees, tees, caps, concentric reducers, eccentric reducers, and flanged short joints. All products in this category of the company comply with ASTM A403, ASEM B16.9, and ASTM A234 standards. Welded pipe fittings are mainly suitable for high-pressure pipelines that require high pressure in petrochemical, pharmaceutical and health, power, aerospace, fire protection, metallurgy, shipbuilding, gas, nuclear power, and environmental protection, as well as equipment with precise size requirements and various other high-pressure fields.

| Note 1—Where an ellipsis (...) appears in this table, there is no requirement. | |||||||||||||

| GradeA | Composition, % | ||||||||||||

| Grade WP | Grade CR | UNS Designation | CB | MnB | PB | SB | SiB | Ni | Cr | Mo | Ti | N₂CC | Others |

| WPXM19 | CRXM19 | S20910 | 0.06 | 4.0-6.0 | 0.045 | 0.030 | 1.00 | 11.5-13.5 | 20.5-23.5 | 1.50-3.00 | ... | 0.20-0.40 | D |

| WP304 | CR304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ... | ... | ||

| WP304L | CR304L | S30403 | 0.030E | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-12.0 | 18.0-20.0 | ... | ... | ||

| WP304H | CR304H | S30409 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ... | ... | ||

| WP304N | CR304N | S30451 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ... | ... | 0.10-0.16 | |

| WP304LN | CR304LN | S30453 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ... | ... | 0.10-0.16 | |

| WP309 | CR309 | S30900 | 0.20 | 2.00 | 0.045 | 0.030 | 1.00 | 12.0-15.0 | 22.0-24.0 | ... | ... | ||

| WP310S | CR310S | S31008 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 19.0-22.0 | 24.0-26.0 | ... | ... | ||

| WPS31254 | CRS31254 | S31254 | 0.020 | 1.00 | 0.030 | 0.010 | 0.80 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | ... | 0.18-0.22 | Cu 0.50-1.00 |

| WP316 | CR316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | ... | ||

| WP316L | CR316L | S31603 | 0.030E | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0F | 16.0-18.0 | 2.00-3.00 | ... | ||

| WP316H | CR316H | S31609 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | ... | ||

| WP316N | CR316N | S31651 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-13.0 | 16.0-18.0 | 2.00-3.00 | ... | 0.10-0.16 | |

| WP316LN | CR316LN | S31653 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-13.0 | 16.0-18.0 | 2.00-3.00 | ... | 0.10-0.16 | |

| WP317 | CR317 | S31700 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | ... | ||

| WP317L | CR317L | S31703 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | ... | ||

| WPS31725 | CRS31725 | S31725 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 13.5-17.5 | 18.0-20.0 | 4.0-5.0 | ... | 0.20 | |

| WPS31726 | CRS31726 | S31726 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 13.5-17.5 | 17.0-20.0 | 4.0-5.0 | ... | 0.10-0.20 | |

| WP321 | CR321 | S32100 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | G | ... | |

| WP321H | CR321H | S32109 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | H | ... | |

| WPS33228 | CRS33228 | S33228 | 0.04-0.08 | 1.00 | 0.030 | 0.015 | 0.30 | 31.0-33.0 | 26.0-28.0 | ... | ... | Ce 0.05-0.10 AI 0.025 Cb 0.6-1.0 | |

| WPS34565 | CRS34565 | S34565 | 0.030 | 5.0-7.0 | 0.030 | 0.010 | 1.00 | 16.0-18.0 | 23.0-25.0 | 4.0-5.0 | ... | 0.40-0.60 | Cb 0.10 |

| WP347 | CR347 | S34700 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | ... | ... | I |

| WP347H | CR347H | S34709 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | ... | ... | J |

| WP348 | CR348 | S34800 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | ... | ... | Cb+Ta=10×(C)-1.10 Ta0.10 Co 0.20 |

| WP348H | CR348H | S34809 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | ... | ... | Cb+Ta=8×(C)-1.10 Ta 0.10 Co 0.20 |

| WPS38815 | CRS38815 | S38815 | 0.030 | 2.00 | 0.040 | 0.020 | 5.5-6.5 | 13.0-17.0 | 13.0-15.0 | 0.75-1.50 | ... | ... | Cu 0.75-1.50 Al 0.30 |

A. See Section 15 for marking requirements.

B. Maximum, unless otherwise indicated.

C. The method of analysis for nitrogen shall be a matter of agreement between the purchaser and manufacturer.

D. Columbium 0.10-0.30 %; Vanadium, 0.10-0.30%.

E. For small diameter or thin walls, or both, where many drawing passes are required, a carbon maximum of 0.040% is necessary in grades TP304L and TP316L. Small outside diameter tubes are defined as those less than 0.500 in. [12.1 mm] in our side diameter and light wall tubes as those less than 0.049 in. [1.24 mm] in average wall thickness.

F. On pierced tubing, the nickel may be 11.0-16.0%.

G. 5x(C+N₂)-0.70.

H. 4x(C+N₂)-0.70.

I. The columbium content shall be not less than ten times the carbon content and not more than 1.10%.

J. The columbium content shall be not less than eight times the carbon content and not more than 1.10%.

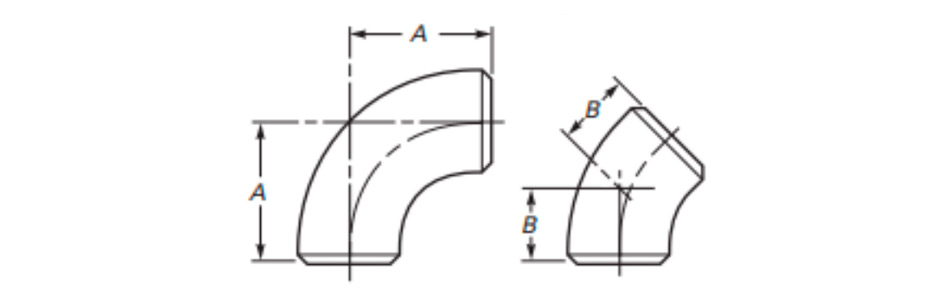

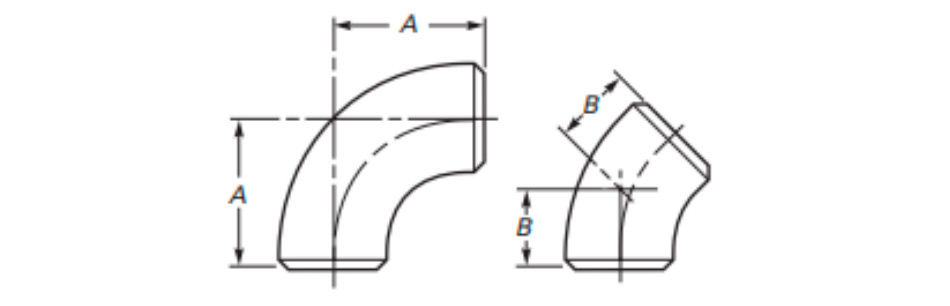

Nominal Pipe Size(NPS) | Outside Diameter at Bevel | Center-to-End | |

| 90-deg Elbows, A | 45-deg Elbows, B | ||

| ½ | 21.3 | 38 | 16 |

| ¾ | 26.7 | 38 | 19 |

| 1 | 33.4 | 38 | 22 |

| 1¼ | 42.2 | 48 | 25 |

| 1½ | 48.3 | 57 | 29 |

| 2 | 60.3 | 76 | 35 |

| 2½ | 73.0 | 95 | 44 |

| 3 | 88.9 | 114 | 51 |

| 3½ | 101.6 | 133 | 57 |

| 4 | 114.3 | 152 | 64 |

| 5 | 141.3 | 190 | 79 |

| 6 | 168.3 | 229 | 95 |

| 8 | 219.1 | 305 | 127 |

| 10 | 273.0 | 381 | 159 |

| 12 | 323.8 | 457 | 190 |

| 14 | 355.6 | 533 | 222 |

| 16 | 406.4 | 610 | 254 |

| 18 | 457.0 | 686 | 286 |

| 20 | 508.0 | 762 | 318 |

| 22 | 559.0 | 838 | 343 |

| 24 | 610.0 | 914 | 381 |

| 26 | 660.0 | 991 | 406 |

| 28 | 711.0 | 1 067 | 438 |

| 30 | 762.0 | 1 143 | 470 |

| 32 | 813.0 | 1 219 | 502 |

| 34 | 864.0 | 1 295 | 533 |

| 36 | 914.0 | 1 372 | 565 |

| 38 | 965.0 | 1448 | 600 |

| 40 | 1 016.0 | 1 524 | 632 |

| 42 | 1 067.0 | 1 600 | 660 |

| 44 | 1 118.0 | 1 676 | 695 |

| 46 | 1 168.0 | 1 753 | 727 |

| 48 | 1 219.0 | 1 829 | 759 |

GENERAL NOTE: All dimensions are in millimeters.

Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Center- to-End, A | Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Center to-End, A | ||

| Large End | Small End | Large End | Small End | ||||

| 2 × 1½ | 60.3 | 48.3 | 76 | 10 × 8 | 273.0 | 219.1 | 381 |

| 2 × 1¼ | 60.3 | 42.2 | 76 | 10 × 6 | 273.0 | 168.3 | 381 |

| 2 × 1 | 60.3 | 33.4 | 76 | 10 × 5 | 273.0 | 141.3 | 381 |

| 2½ × 2 | 73.0 | 60.3 | 95 | 12 × 10 | 323.8 | 273.0 | 457 |

| 2½ × 1½ | 73.0 | 48.3 | 95 | 12 × 8 | 323.8 | 219.1 | 457 |

| 2½ × 1¼ | 73.0 | 42.2 | 95 | 12 × 6 | 323.8 | 168.3 | 457 |

| 3 × 2½ | 88.9 | 73.0 | 114 | 14 × 12 | 355.6 | 323.8 | 533 |

| 3 × 2 | 88.9 | 60.3 | 114 | 14 × 10 | 355.6 | 273.0 | 533 |

| 3 × 1½ | 88.9 | 48.3 | 114 | 14 × 8 | 355.6 | 219.1 | 533 |

| 3½ × 3 | 101.6 | 88.9 | 133 | 16 × 14 | 406.4 | 355.6 | 610 |

| 3½ × 2½ | 101.6 | 73.0 | 133 | 16 × 12 | 406.4 | 323.8 | 610 |

| 3½ × 2 | 101.6 | 60.3 | 133 | 16 × 10 | 406.4 | 273.0 | 610 |

| 4 × 3½ | 114.3 | 101.6 | 152 | 18 × 16 | 457.0 | 406.4 | 686 |

| 4 × 3 | 114.3 | 88.9 | 152 | 18 × 14 | 457.0 | 355.6 | 686 |

| 4 × 2½ | 114.3 | 73.0 | 152 | 18 × 12 | 457.0 | 323.8 | 686 |

| 4 × 2 | 114.3 | 60.3 | 152 | 18 × 10 | 457.0 | 273.0 | 686 |

| 5 × 4 | 141.3 | 114.3 | 190 | 20 × 18 | 508.0 | 457.0 | 762 |

| 5 × 3½ | 141.3 | 101.6 | 190 | 20 × 16 | 508.0 | 406.4 | 762 |

| 5 × 3 | 141.3 | 88.9 | 190 | 20 × 14 | 508.0 | 355.6 | 762 |

| 5 × 2½ | 141.3 | 73.0 | 190 | 20 × 12 | 508.0 | 323.8 | 762 |

| 20 × 10 | 508.0 | 273.0 | 762 | ||||

| 6 × 5 | 168.3 | 141.3 | 229 | ||||

| 6 × 4 | 168.3 | 114.3 | 229 | 24 × 22 | 610 | 559 | 914 |

| 6 × 3½ | 168.3 | 101.6 | 229 | 24 × 20 | 610 | 508 | 914 |

| 6 × 3 | 168.3 | 88.9 | 229 | 24 × 18 | 610 | 457 | 914 |

| 24 × 16 | 610 | 406.4 | 914 | ||||

| 8 × 6 | 219.1 | 168.3 | 305 | 24 × 14 | 610 | 355.6 | 914 |

| 8 × 5 | 219.1 | 141.3 | 305 | 24 × 12 | 610 | 323.8 | 914 |

| 8 × 4 | 219.1 | 114.3 | 305 | ... | ... | ... | ... |

GENERAL NOTE: All dimensions are in millimeters.

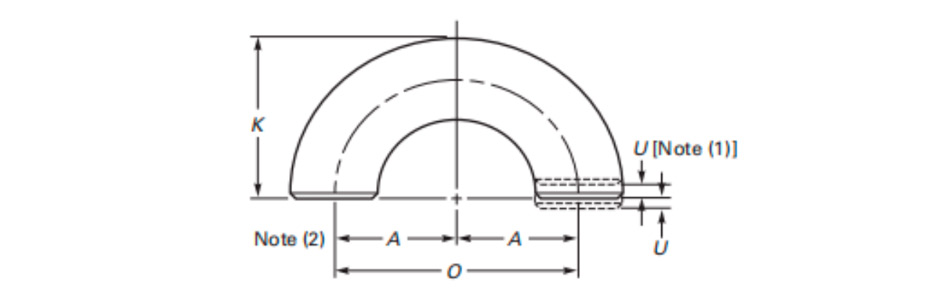

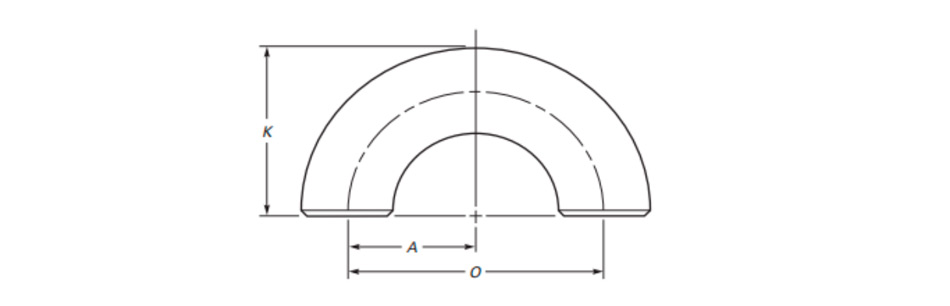

| Nominal Pipe Size (NPS) | 0ut side Diameter at Bevel | Center-to-Center, O | Badke to Face, K |

| ½ | 21.3 | 76 | 48 |

| ¾ | 26.7 | 76 | 51 |

| 1 | 33.4 | 76 | 56 |

| 1¼ | 42.2 | 95 | 70 |

| 1½ | 48.3 | 114 | 83 |

| 2 | 60.3 | 152 | 106 |

| 2½ | 73 | 190 | 132 |

| 3 | 88.9 | 229 | 159 |

| 3½ | 101.6 | 267 | 184 |

| 4 | 114.3 | 305 | 210 |

| 5 | 141.3 | 381 | 262 |

| 6 | 168.3 | 457 | 313 |

| 8 | 219.1 | 610 | 414 |

| 10 | 273 | 762 | 518 |

| 12 | 323.8 | 914 | 619 |

| 14 | 355.6 | 1 067 | 711 |

| 16 | 406.4 | 1 219 | 813 |

| 18 | 457 | 1 372 | 914 |

| 20 | 508 | 1 524 | 1 016 |

| 22 | 559 | 1 676 | 1 118 |

| 24 | 610 | 1 829 | 1 219 |

GENERAL NOTE: All dimensions are in millimeters.

NOTE:

(1) See Table 13 for tolerance for alignment of ends U.

(2) Dimension A is equal to one-half of dimension O.

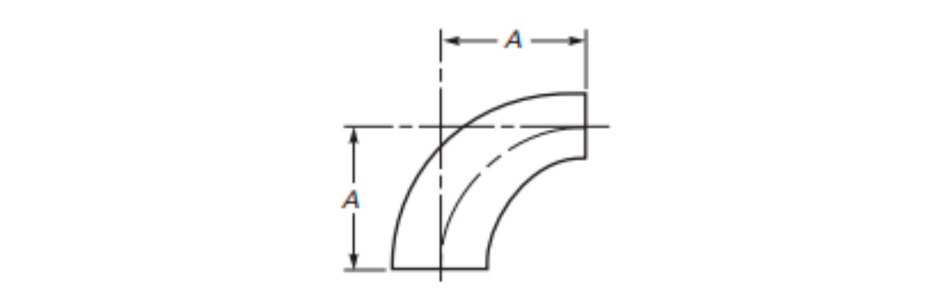

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Center-to-End, A |

| 1 | 33.4 | 25 |

| 1¼ | 42.2 | 32 |

| 1½ | 48.3 | 38 |

| 2 | 60.3 | 51 |

| 2½ | 73.0 | 64 |

| 3 | 88.9 | 76 |

| 3½ | 101.6 | 89 |

| 4 | 114.3 | 102 |

| 5 | 141.3 | 127 |

| 6 | 168.3 | 152 |

| 8 | 219.1 | 203 |

| 10 | 273.0 | 254 |

| 12 | 323.8 | 305 |

| 14 | 355.6 | 356 |

| 16 | 406.4 | 406 |

| 18 | 457.0 | 457 |

| 20 | 508.0 | 508 |

| 22 | 559.0 | 559 |

| 24 | 610.0 | 610 |

GENERAL NOTE: All dimensions are in millimeters.

Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Center- to-Center, O | Back to Face, K |

| 1 | 33.4 | 51 | 41 |

| 1¼ | 42.2 | 64 | 52 |

| 1½ | 48.3 | 76 | 62 |

| 2 | 60.3 | 102 | 81 |

| 2½ | 73 | 127 | 100 |

| 3 | 88.9 | 152 | 121 |

| 3½ | 101.6 | 178 | 140 |

| 4 | 114.3 | 203 | 159 |

| 5 | 141.3 | 254 | 197 |

| 6 | 168.3 | 305 | 237 |

| 8 | 219.1 | 406 | 313 |

| 10 | 273.0 | 508 | 391 |

| 12 | 323.8 | 610 | 467 |

| 14 | 355.6 | 711 | 533 |

| 16 | 406.4 | 813 | 610 |

| 18 | 457.0 | 914 | 686 |

| 20 | 508.0 | 1 016 | 762 |

| 22 | 559.0 | 1 118 | 838 |

| 24 | 610.0 | 1 219 | 914 |

GENERAL NOTES:

(a) All dimensions are in millimeters.

(b) Dimension A is equal to one-half of dimension O.

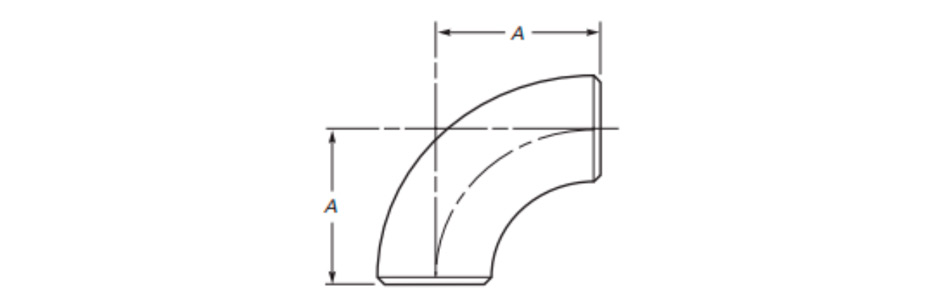

Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Center-to-End | |

90-deg Elbows, A | 45-deg Elbows, B | ||

| ¾ | 26.7 | 57 | 24 |

| 1 | 33.4 | 76 | 31 |

| 1¼ | 42.2 | 95 | 39 |

| 1½ | 48.3 | 114 | 47 |

| 2 | 60.3 | 152 | 63 |

| 2½ | 73.0 | 190 | 79 |

| 3 | 88.9 | 229 | 95 |

| 3½ | 101.6 | 267 | 111 |

| 4 | 114.3 | 305 | 127 |

| 5 | 141.3 | 381 | 157 |

| 6 | 168.3 | 457 | 189 |

| 8 | 219.1 | 610 | 252 |

| 10 | 273.0 | 762 | 316 |

| 12 | 323.8 | 914 | 378 |

| 14 | 355.6 | 1 067 | 441 |

| 16 | 406.4 | 1 219 | 505 |

| 18 | 457.0 | 1 372 | 568 |

| 20 | 508.0 | 1 524 | 632 |

| 22 | 559.0 | 1 676 | 694 |

| 24 | 610.0 | 1 829 | 757 |

| 26 | 660.0 | 1 981 | 821 |

| 28 | 711.0 | 2 134 | 883 |

| 30 | 762.0 | 2 286 | 964 |

| 32 | 813.0 | 2 438 | 1 010 |

| 34 | 864.0 | 2 591 | 1 073 |

| 36 | 914.0 | 2 743 | 1 135 |

| 38 | 965.0 | 2 896 | 1 200 |

| 40 | 1 016.0 | 3 048 | 1 264 |

| 42 | 1 067.0 | 3 200 | 1 326 |

| 44 | 1 118.0 | 3 353 | 1 389 |

| 46 | 1 168.0 | 3 505 | 1 453 |

| 48 | 1 219.0 | 3 658 | 1 516 |

GENERAL NOTES: All dimensions are in millimeters.

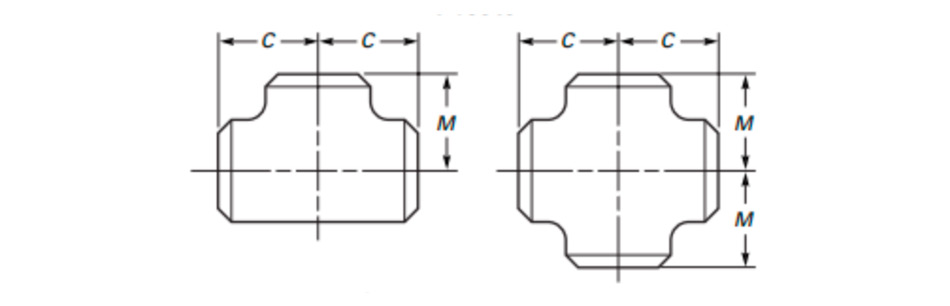

Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Center-to-End | |

| Run, C | Outlet, M [Notes (1) and (2)] | ||

| ½ | 21.3 | 25 | 25 |

| ¾ | 26.7 | 29 | 29 |

| 1 | 33.4 | 38 | 38 |

| 1¼ | 42.2 | 48 | 48 |

| 1½ | 48.3 | 57 | 57 |

| 2 | 60.3 | 64 | 64 |

| 2½ | 73.0 | 76 | 76 |

| 3 | 88.9 | 86 | 86 |

| 3½ | 101.6 | 95 | 95 |

| 4 | 114.3 | 105 | 105 |

| 5 | 141.3 | 124 | 124 |

| 6 | 168.3 | 143 | 143 |

| 8 | 219.1 | 178 | 178 |

| 10 | 273.0 | 216 | 216 |

| 12 | 323.8 | 254 | 254 |

| 14 | 355.6 | 279 | 279 |

| 16 | 406.4 | 305 | 305 |

| 18 | 457.0 | 343 | 343 |

| 20 | 508.0 | 381 | 381 |

| 22 | 559.0 | 419 | 419 |

| 24 | 610.0 | 432 | 432 |

| 26 | 660.0 | 495 | 495 |

| 28 | 771.0 | 521 | 521 |

| 30 | 762.0 | 559 | 559 |

| 32 | 813.0 | 597 | 597 |

| 34 | 864.0 | 635 | 635 |

| 36 | 914.0 | 673 | 673 |

| 38 | 965.0 | 711 | 711 |

| 40 | 1 016.0 | 749 | 749 |

| 42 | 1 067.0 | 762 | 711 |

| 44 | 1 118.0 | 813 | 762 |

| 46 | 1 168.0 | 851 | 800 |

| 48 | 1 219.0 | 889 | 838 |

GENERAL NOTE: All dimensions are in millimeters.

NOTES:

(1) Outlet dimension M for NPS 26 and larger is recommended but not required.

(2) Dimensions applicable to crosses NPS 24 and smaller.

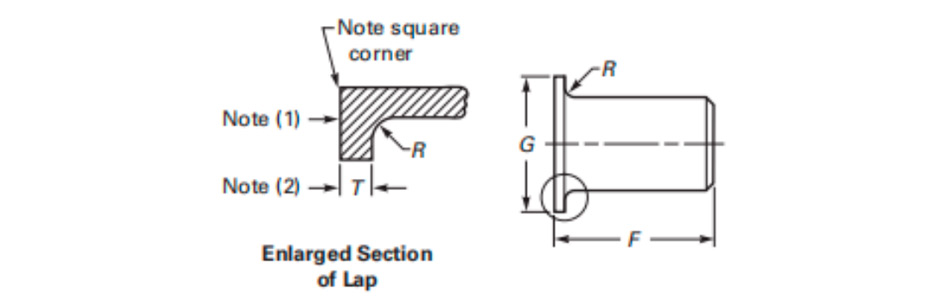

Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Long Pattern Length, F [Notes (3), (4)] | Short Pattern Length, F [Notes (3), (4)] | Radius of FiIllet, R [Note (5)] | Diameter of Lap, G [Note (6)] | |

| Max. | Min. | |||||

| ½ | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| ¾ | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1 | 35.0 | 32.6 | 102 | 51 | 3 | 51 |

| 1¼ | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 1½ | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2½ | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3½ | 104.0 | 100.8 | 152 | 76 | 10 | 140 |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 12 | 328.0 | 323.1 | 254 | 152 | 13 | 381 |

| 14 | 359.9 | 354.8 | 305 | 152 | 13 | 413 |

| 16 | 411.0 | 405.6 | 305 | 152 | 13 | 470 |

| 18 | 462.0 | 456.0 | 305 | 152 | 13 | 533 |

| 20 | 514.0 | 507.0 | 305 | 152 | 13 | 584 |

| 22 | 565.0 | 558.0 | 305 | 152 | 13 | 641 |

| 24 | 616.0 | 609.0 | 305 | 152 | 13 | 692 |

GENERAL NOTES:

(a) All dimensions are in millimeters.

(b) See Table 13 for tolerances.

(c) Service conditions and joint construction often dictate stub end length requirements. Therefore, the purchaser must specify long or short pattern fitting when ordering.

NOTES:

(1) Gasket face finish shall be in accordance with ASME B16.5 for raised face flanges.

(2) The lap thickness T shall not be less than the nominal pipe wall thickness. See Table 13 for maximum tolerance.

(3) When short pattern stub ends are used with larger flanges in classes 300 and 600, with most sizes in Classes 900 and higher, and when long pattern stub ends are used with larger flanges in Classes 1500 and 2500, it may be necessary to increase the length of the stub ends in order to avoid covering the weld with the flange. Such increases in length should be a matter of agreement between the manufacturer and purchaser.

(4) When special facings such as tongue and groove, male and female, etc, are employed, additional lap thickness must be printed and such additional thickness shall be in addition to (not included in) the basic length F.

(5) These dimensions conform to the radius established for lap joint flanges in ASME B16.5.

(6) This dimension conforms to standard machined facings shown in ASME B16.5. The back face of the lap shall be machined to conform to the surface on which it seats. Where ring joint facings are to be applied, use dimension K as given in ASME B16.5.

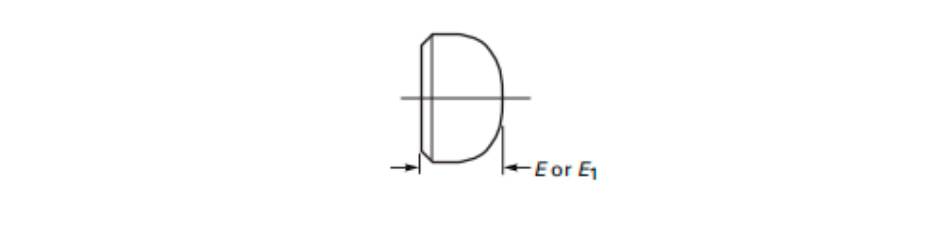

Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Length, E [Notes (1)] | Limiting Wall Thickness for Length, E | Length, E1 [Notes (2)] |

| ½ | 21.3 | 25 | 4.57 | 25 |

| ¾ | 26.7 | 25 | 3.81 | 25 |

| 1 | 33.4 | 38 | 4.57 | 38 |

| 1¼ | 42.2 | 38 | 4.83 | 38 |

| 1½ | 48.3 | 38 | 5.08 | 38 |

| 2 | 60.3 | 38 | 5.59 | 44 |

| 2½ | 73.0 | 38 | 7.11 | 51 |

| 3 | 88.9 | 51 | 7.62 | 64 |

| 3½ | 101.6 | 64 | 8.13 | 76 |

| 4 | 114.3 | 64 | 8.64 | 76 |

| 5 | 141.3 | 76 | 9.65 | 89 |

| 6 | 168.3 | 89 | 10.92 | 102 |

| 8 | 219.1 | 102 | 12.70 | 127 |

| 10 | 273.0 | 127 | 12.70 | 152 |

| 12 | 323.8 | 152 | 12.70 | 178 |

| 14 | 355.6 | 165 | 12.70 | 191 |

| 16 | 406.4 | 178 | 12.70 | 203 |

| 18 | 457.0 | 203 | 12.70 | 229 |

| 20 | 508.0 | 229 | 12.70 | 254 |

| 22 | 559.0 | 254 | 12.70 | 254 |

| 24 | 610.0 | 267 | 12.70 | 305 |

| 26 | 660.0 | 267 | ... | ... |

| 28 | 711.0 | 267 | ... | ... |

| 30 | 762.0 | 267 | ... | ... |

| 32 | 813.0 | 267 | ... | ... |

| 34 | 864.0 | 267 | ... | ... |

| 36 | 914.0 | 267 | ... | ... |

| 38 | 965.0 | 305 | ... | ... |

| 40 | 1 016.0 | 305 | ... | ... |

| 42 | 1 067.0 | 305 | ... | ... |

| 44 | 1 118.0 | 343 | ... | ... |

| 46 | 1 168.0 | 343 | ... | ... |

| 48 | 1 219.0 | 343 | ... | ... |

GENERAL NOTES:

(a) All dimensions are in millimeters.

(b) The shape of these caps shall be ellipsoidal and shall conform to the requirements given in the ASME Boiler and Pressure Vessel Code.

NOTES:

(1) Length E applies for thickness not exceeding that given in column "Limiting wal Thickness for Length, E.”

(2) Length E1 applies for thickness greater than that given in column“Limiting wall Thickness" for NPS 24 and smaller. For NPS 26 and larger, length E1 shall be by agreement between the manufacturer and purchaser.

KIDY is a service-oriented enterprise that provides fittings for changing the direction of pipelines in pipeline systems. Butt welded elbows are made by welding two steel plates. Generally, large-diameter elbows are butt welded, so in industrial applications, elbows with a diameter of 600 or above are mostly butt welded. 90 ° butt welded elbows can be divided into long radius (LR) elbows and short radius (SR) elbows based on the bending radius. Other commonly used elbows in fluid pipeline engineering construction include 45 ° elbows and 180 ° elbows. Our company can also customize other non-standard elbows according to engineering needs.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.