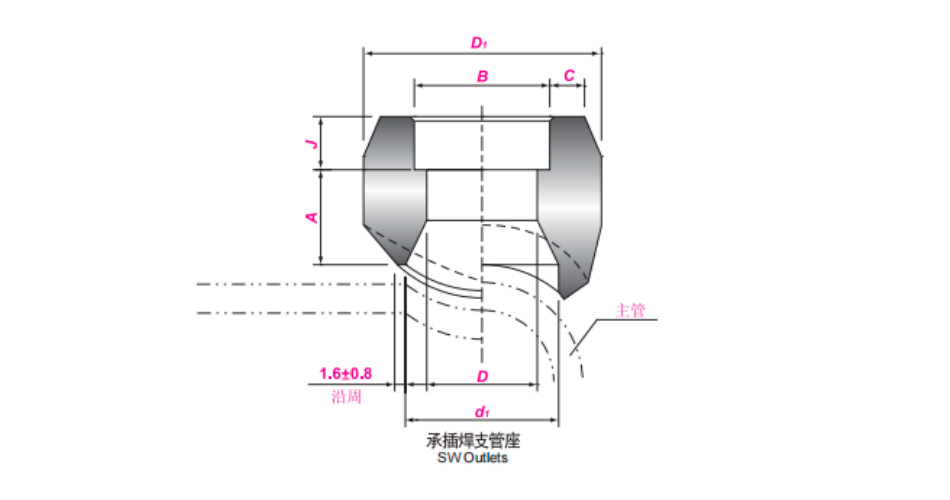

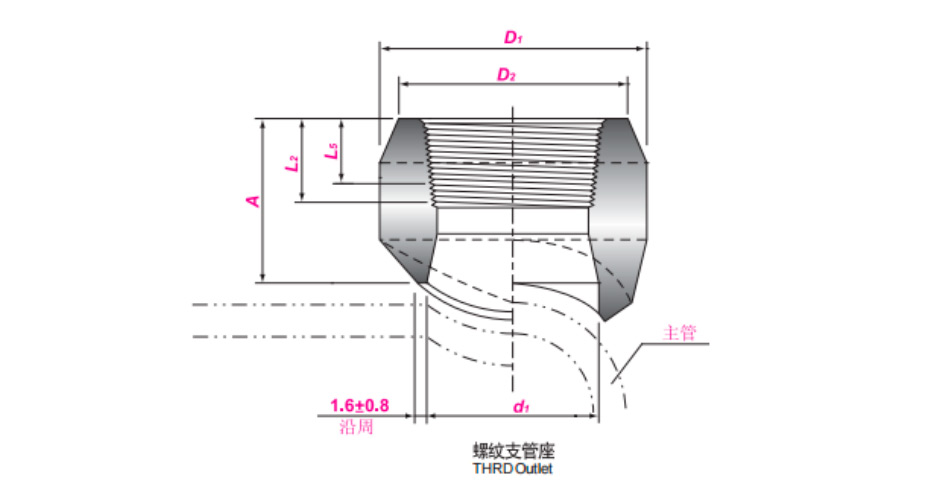

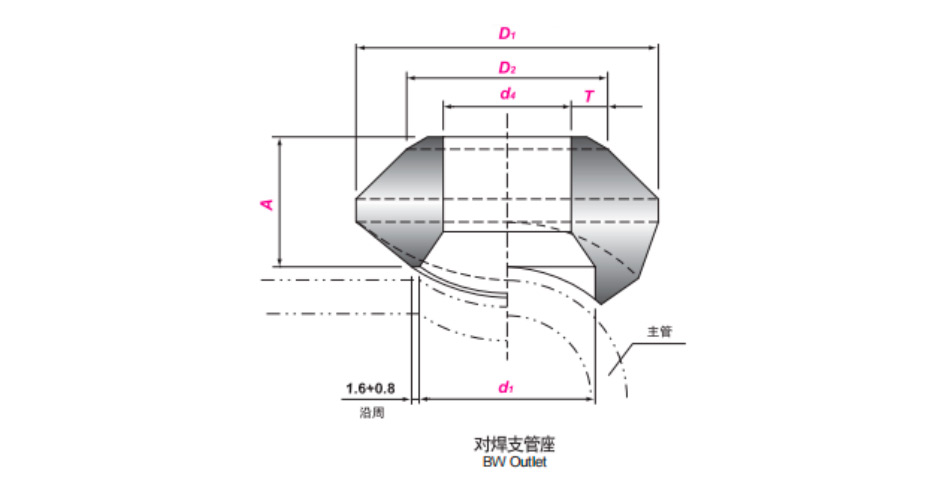

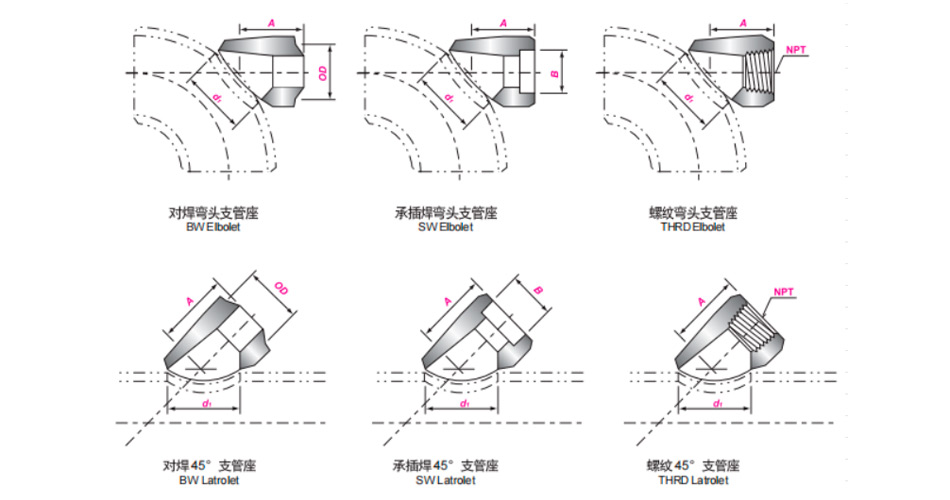

MSS SP97 Reinforced pipe fittings used for branch connections, replacing traditional branch connection types such as reducing tees, reinforcing plates, and reinforced pipe sections, have outstanding advantages such as safety and reliability, cost reduction, simple construction, improved medium flow channels, series standardization, and convenient design selection. They are increasingly used in high-pressure, high-temperature, large-diameter, and thick walled pipelines, replacing traditional branch connection methods. The main body of the branch pipe seat is made of high-quality forgings, which are made of the same materials as the pipeline, including carbon steel, alloy steel, stainless steel, etc. Both the branch pipe and the main pipe are welded, and the connection between the branch pipe seat and the branch pipe or other pipes (such as short pipes, plugs, etc.), instruments, and valves can be in various forms such as butt welding, socket welding, and threading. Branch pipe supports are divided into six types: butt welded branch pipe supports, socket branch pipe supports, threaded branch pipe supports, short pipe branch pipe supports, diagonal branch pipe supports, and elbow branch pipe supports.

| Nominal Size | Birch Nominal Size | Depth of Socket | Face of fitting to Crotch | OD of Fitting | Socket Wall Thickness | Cut Hole Dia. | ||||||

| DN | NPS | DN | NPS | Jmin | Amax | Dfmin | Cmin | df | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 9.5 | 10 | - | 27 | - | 3.18 | - | 16 | - |

| 10~900 | 3/8~36 | 8 | 1/4 | 9.5 | 10 | - | 27 | - | 3.78 | - | 16 | - |

| 15~900 | 1/2~36 | 10 | 3/8 | 9.5 | 13 | - | 30 | - | 4.01 | - | 19 | - |

| 20~900 | 3/4~36 | 15 | 1/2 | 9.5 | 16 | 24 | 38 | 47 | 4.67 | 5.97 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 12.5 | 16 | 25 | 47 | 53 | 4.90 | 6.96 | 30 | 25 |

| 32~900 | 1¼.~36 | 25 | 1 | 12.5 | 22 | 29 | 56 | 63 | 5.69 | 7.92 | 36 | 33 |

| 40~900 | 1½-~36 | 32 | 1¼ | 12.5 | 22 | 30 | 66 | 74 | 6.07 | 7.92 | 45 | 38 |

| 50~900 | 2~36 | 40 | 1½ | 12.5 | 24 | 32 | 75 | 83 | 6.35 | 8.92 | 51 | 49 |

| 65~900 | 2½~36 | 50 | 2 | 16.0 | 24 | 37 | 90 | 104 | 6.93 | 10.92 | 65 | 59 |

| 80~900 | 3~36 | 65 | 2½ | 16.0 | 25 | - | 105 | - | 8.76 | - | 76 | - |

| 100~900 | 4~36 | 80 | 3 | 16.0 | 30 | - | 124 | - | 9.52 | - | 94 | - |

| 125~900 | 5~36 | 100 | 4 | 19.0 | 30 | - | 154 | - | 10.69 | - | 121 | - |

Note: 1) As for the sizes of socket diameter B and bore D, please refer to the ones in the page of 30.

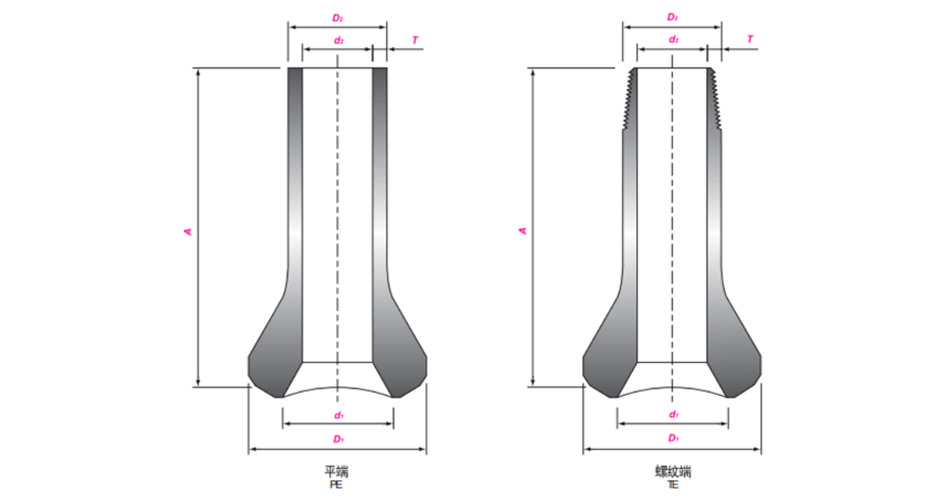

| Run Pipes Nominal Size | Branch Nominal Size | Length | OD a Fitting | OD at End ad Branch | Length of Thread | Cut Hole Dia. | ||||||

| DN | NPS | DN | NPS | A | Dfmin | D2min | L2min | df | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8-900 | 1/4~ 36 | 6 | 1/8 | 19 | - | 27 | - | 22 | - | 6.7 | 16 | - |

| 10~900 | 3/8~36 | 8 | 1/4 | 19 | - | 27 | - | 22 | - | 10.2 | 16 | - |

| 15~900 | 1/2~36 | 10 | 3/8 | 21 | - | 30 | - | 25 | - | 10.4 | 19 | - |

| 20~900 | 3/4~36 | 15 | 1/2 | 25 | 32 | 38 | 45 | 33 | 42 | 13.6 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 27 | 37 | 47 | 52 | 39 | 48 | 13.9 | 30 | 25 |

| 32~900 | 1¼-36 | 25 | 1 | 33 | 40 | 56 | 63 | 48 | 58 | 17.3 | 36 | 33 |

| 40~900 | 1½~36 | 32 | 1¼ | 33 | 41 | 66 | 72 | 58 | 67 | 18.8 | 45 | 38 |

| 50~900 | 2~36 | 40 | 1 | 35 | 43 | 75 | 83 | 64 | 77 | 18.4 | 51 | 49 |

| 65~900 | 2½~36 | 50 | 2 | 38 | 52 | 90 | 104 | 77 | 93 | 19.2 | 65 | 59 |

| 80~900 | 3~36 | 65 | 2½ | 46 | - | 105 | - | 94 | - | 28.9 | 76 | - |

| 100-900 | 4~36 | 80 | 3 | 51 | - | 124 | - | 114 | - | 30.5 | 94 | - |

| 125~900 | 5~36 | 100 | 4 | 57 | - | 154 | - | 140 | - | 33 | 121 | - |

Note: 1) Thread shall be machined per GB/T: 12716 (equivalent to ASME B1.20.1).

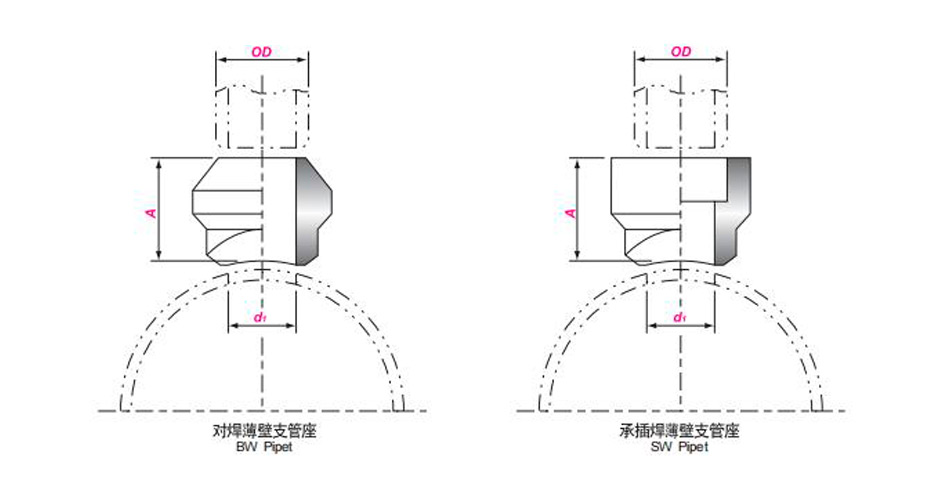

| Run Pipes Nominal Size | Branch Nominal Size | Length | OD a Fitting | Cut Hole Dia. | ||||||||

| DN | NPS | DN | NPS | A | D2min | df | ||||||

| STD | NPS | SCH160 | STD | NPS | SCH160 | STD | NPS | SCH160 | ||||

| 8~900 | 1/4~36 | 6 | 1/8 | 16 | 16 | - | 24 | 24 | - | 16 | 16 | - |

| 10~900 | 3/8~36 | 8 | 1/4 | 16 | 16 | - | 26 | 26 | - | 16 | 16 | - |

| 15~900 | 1/2~36 | 10 | 3/8 | 19 | 19 | - | 30 | 30 | - | 19 | 19 | - |

| 20~900 | 3/4~36 | 15 | 1/2 | 19 | 19 | 28 | 36 | 36 | 36 | 24 | 24 | 14 |

| 25~900 | 1~36 | 20 | 3/4 | 22 | 22 | 32 | 43 | 43 | 46 | 30 | 30 | 19 |

| 32~900 | 1¼~36 | 25 | 1 | 27 | 27 | 38 | 55 | 55 | 51 | 36 | 36 | 25 |

| 40~900 | 1½~36 | 32 | 1¼ | 32 | 32 | 44 | 66 | 66 | 63 | 45 | 45 | 33 |

| 50~900 | 2~36 | 40 | 1½ | 33 | 33 | 51 | 74 | 74 | 71 | 51 | 51 | 38 |

| 65~900 | 2½~36 | 50 | 2 | 38 | 38 | 55 | 90 | 90 | 82 | 65 | 65 | 43 |

| 80~900 | 3~36 | 65 | 2½ | 41 | 41 | 62 | 104 | 104 | 98 | 76 | 76 | 54 |

| 90~900 | 3½~36 | 80 | 3 | 44 | 44 | 73 | 124 | 124 | 122 | 93 | 93 | 73 |

| 100~900 | 4~36 | 90 | 3½ | 48 | 48 | - | 138 | 138 | - | 113 | 113 | - |

| 125~900 | 5~36 | 100 | 4 | 51 | 51 | 84 | 154 | 154 | 154 | 120 | 120 | 98 |

| 150~900 | 6~36 | 125 | 5 | 57 | 57 | 94 | 187 | 187 | 188 | 141 | 141 | 122 |

| 200~900 | 8~36 | 150 | 6 | 60 | 78 | 105 | 213 | 227 | 222 | 170 | 170 | 146 |

| 250~900 | 10~36 | 200 | 8 | 70 | 99 | - | 265 | 292 | - | 220 | 220 | - |

| 300~900 | 12~36 | 250 | 10 | 78 | 94 | - | 323 | 325 | - | 275 | 265 | - |

| 350~900 | 14~36 | 300 | 12 | 86 | 103 | - | 379 | 391 | - | 325 | 317 | - |

| 400~900 | 16~36 | 350 | 14 | 89 | 100 | - | 411 | 416 | - | 357 | 351 | - |

| 450~900 | 18~36 | 400 | 15 | 94 | 106 | - | 465 | 468 | - | 408 | 403 | - |

| 500~900 | 20~36 | 450 | 18 | 97 | 111 | - | 522 | 525 | - | 459 | 455 | - |

| 550~900 | 22~36 | 500 | 20 | 102 | 119 | - | 573 | 584 | - | 508 | 509 | - |

| 650~900 | 26~36 | 600 | 24 | 116 | 140 | - | 690 | 708 | - | 614 | 612 | - |

Note:

1) D2 is same to the outside diameter of branch pipe, d4 is same to the inside diameter of branch pipe, T is same to the wall thickness of branch pipe.

2) As to the bevel ends of the branch pipe, please refer to the figure in the page of 21.

| Run Pipes Nominal Size | Branch Nominal Size | Length | Cut Hole Dia. | ||||||||

| DN | NPS | DN | NPS | A | df | ||||||

| BW | SW and THRD | BW | SW and THRD | ||||||||

| STD, XS | SCH160 | 3000 | 6000 | STD, XS | SCH160 | 3000 | 6000 | ||||

| 20~900 | 3/4~36 | 15 | 1/2 | 45 | 50 | 45 | 50 | 31 | 30 | 31 | 30 |

| 25~900 | 1~36 | 20 | 3/4 | 50 | 58 | 50 | 58 | 42 | 40 | 42 | 40 |

| 32~900 | 1¼~36 | 25 | 1 | 60 | 70 | 60 | 70 | 54 | 50 | 54 | 50 |

| 40~900 | 1½~36 | 32 | 1¼ | 68 | 76 | 68 | 76 | 61 | 58 | 61 | 58 |

| 50~900 | 2~36 | 40 | 1½ | 75 | 83 | 75 | 83 | 76 | 66 | 76 | 66 |

| 65~900 | 2½~36 | 50 | 2 | 90 | 98 | 90 | 98 | 90 | 83 | 90 | 83 |

| 80~900 | 3~36 | 65 | 2½ | 95 | 105 | - | - | 100 | 95 | - | - |

| 90~900 | 3½~36 | 80 | 3 | 120 | 130 | - | - | 132 | 115 | - | - |

| 125~900 | 5~36 | 100 | 4 | 140 | 150 | - | - | 168 | 150 | - | - |

| 200~900 | 8~36 | 150 | 6 | 195 | 210 | - | - | 238 | 225 | - | - |

| 250~900 | 10~36 | 200 | 8 | 220 | - | - | - | 338 | - | - | - |

| 300~900 | 12~36 | 250 | 10 | 270 | - | - | - | 432 | - | - | - |

| 350~900 | 14~36 | 300 | 12 | 290 | - | - | - | 498 | - | - | - |

| Run Pipes Nominal Size | Branch Nominal Size | Length | OD at End | OD of Fitting | Cut Hole Dia. | ||||

| DN | NPS | DN | NPS | A | D2 | D1min | df | ||

| XS | SCH160 | XS | SCH160 | ||||||

| 20~900 | 3/4~36 | 15 | 1/2 | 89 | 21.3 | 38 | 47 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 26.7 | 47 | 53 | 30 | 25 | |

| 32~900 | 1¼~36 | 25 | 1 | 33.4 | 56 | 63 | 36 | 33 | |

| 40~900 | 1½~36 | 32 | 1¼ | 89 | 42.2 | 66 | 72 | 45 | 38 |

| 50~900 | 2~36 | 40 | 1½ | 48.3 | 75 | 83 | 51 | 49 | |

| 65~900 | 2½~36 | 50 | 2 | 60.3 | 90 | 104 | 65 | 59 | |

| 80~900 | 3~36 | 65 | 2½ | 89 | 73.0 | 105 | - | 76 | - |

| 90~900 | 3½~36 | 80 | 3 | 88.9 | 124 | - | 94 | - | |

| 125~900 | 5~36 | 100 | 4 | 114.3 | 154 | - | 121 | - | |

Note:

1) This nipple is used to connect the valve at the end of the branch pipe.

2) The tolerance of D2 shall be as: DN15~40 (NPS12~112): ±0.25mm, DN50~100 (NPS2~4): ±0.5mm. T is the thickness of XS or Sch160, df-D2-2T.

3) Per the purchase specification, the ends can be machined as plain or threaded type and the thread shall be machined per GB/T 12716 (equivalent to ASME B1.20.1).

4) Per the purchase specification, the size d A can be machined as 114mm, 140mm and 165mm.

| Run Pipes Nominal Size | Branch Nominal Size | Length | Cut Hole Dia. | ||||

| DN | NPS | DN | NPS | A | df | ||

| BW | SW | Sch5s | Sch10s | ||||

| 8~900 | 1/4~36 | 6 | 1/8 | 16 | - | - | 7.8 |

| 10~900 | 3/8~36 | 8 | 1/4 | 16 | - | - | 10.4 |

| 15~900 | 1/2~36 | 10 | 3/8 | 19 | - | - | 13.8 |

| 20~900 | 3/4~36 | 15 | 1/2 | 19 | 26 | 18.0 | 17.1 |

| 25~900 | 1~36 | 20 | 3/4 | 22 | 27 | 23.4 | 22.5 |

| 32~900 | 1¼~36 | 25 | 1 | 27 | 33 | 30.1 | 27.9 |

| 40~900 | 1½~36 | 32 | 1¼ | 32 | 33 | 38.9 | 36.7 |

| 50~900 | 2~36 | 40 | 1½ | 33 | 35 | 45.0 | 42.8 |

| 65~900 | 2½~36 | 50 | 2 | 38 | 38 | 57.0 | 54.8 |

| 80~900 | 3~36 | 65 | 2½ | 42 | 46 | 68.8 | 66.9 |

| 90~900 | 3½~36 | 80 | 3 | 45 | 51 | 84.7 | 82.8 |

| 100~900 | 4~36 | 90 | 3½ | 48 | - | 97.4 | 95.5 |

| 125~900 | 5~36 | 100 | 4 | 51 | 57 | 110.1 | 108.2 |

| 150~900 | 6~36 | 125 | 5 | 57 | - | 135.8 | 134.5 |

| 200~900 | 8~36 | 150 | 6 | 60 | - | 162.8 | 161.5 |

| 250~900 | 10~36 | 200 | 8 | 70 | - | 213.6 | 211.6 |

| 300~900 | 12~36 | 250 | 10 | 78 | - | 266.2 | 264.6 |

| 350~900 | 14~36 | 300 | 12 | 86 | - | 315.9 | 314.7 |

| 400~900 | 16~36 | 350 | 14 | 89 | - | 347.7 | 346.0 |

| 450~900 | 18~36 | 400 | 16 | 94 | - | 398.8 | 396.8 |

| 500~900 | 20~36 | 450 | 18 | 97 | - | 448.6 | 447.4 |

| 550~900 | 22~36 | 500 | 20 | 102 | - | 498.4 | 496.9 |

| 650~900 | 26~36 | 600 | 24 | 116 | - | 598.9 | 597.3 |

| 800~900 | 32~36 | 750 | 30 | 137 | - | 749.3 | 746.2 |

Note:

1) The pipets are usually used for connection when the schedule of the run pipe is Sch5s or Sch10s.

2) OD is the outside diameter of the connecting branch pipe.

KIDY is a service-oriented enterprise with a complete range of steel grades, including F304, F321, 316L, and F904L. Regular specifications have been prepared with billets for a long time, and the production cycle is fast. Non standard sizes can be customized!

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.