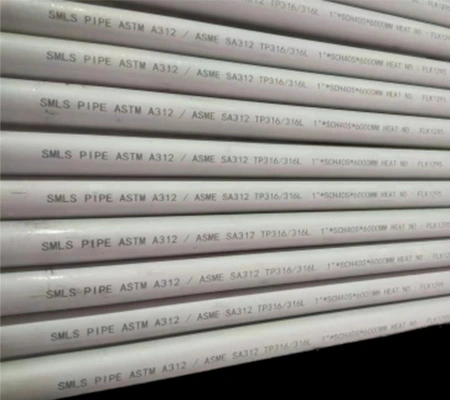

Austenitic stainless steel fluid seamless pipe adopts processing technology, cold drawing or cold rolling forming, specification: 6-813mm, wall thickness: 1-80mm, acid washed surface; Suitable for liquid, particle, and gas transportation pipelines, such as chemical, refining, boilers, electricity, food, and other fields.

| Table1 Chemical Requirements | |||||||||||||||||||

| Grade | UNS Desig-naton | Compositon, % | |||||||||||||||||

| Carbon | Manga nese | Phos phorus | Sulfur | Slicon | Chrom-ium | Nickel | Molyb-denum | Tita-nlum | Colum-bium | Tanta-lum, max | Nitro-genC | Vana-dium | Copper | Cerium | Boron | Alum-inum | Other | ||

| S20400 | 0.03 | 7.0-9.0 | 0.045 | 0.030 | 1.00 | 15.0-17.0 | 1.50-3.00 | ||||||||||||

| TPXM-19 | S20910 | 0.03 | 4.0-6.0 | 0.045 | 0.030 | 1.00 | 20.5-23.5 | 11.5-13.5 | 1.5-3.0 | 0.10-0.30 | 0.15-0.30 | 0.10-0.30 | |||||||

| TPXM-10 | S21900 | 0.06 | 8.0-10.0 | 0.045 | 0.030 | 1.00 | 19.0-21.5 | 5.5-7.5 | 0.20-0.40 | ||||||||||

| TPXM-11 | S21904 | 0.08 | 8.0-10.0 | 0.045 | 0.030 | 1.00 | 19.0-21.5 | 5.5-7.5 | 0.15-0.40 | ||||||||||

| TPXM-29 | S24000 | 0.04 | 11.5-14.5 | 0.060 | 0.030 | 1.00 | 17.0-19.0 | 2.3-3.7 | 0.20-0.40 | ||||||||||

| TP201 | S20100 | 0.08 | 5.5-7.5 | 0.060 | 0.015 | 1.00 | 16.0-18.0 | 3.5-5.5 | 0.25 | ||||||||||

| TP201LN | S20153 | 0.15 | 6.4-7.5 | 0.045 | 0.030 | 0.75 | 16.0-17.5 | 4.0-5.0 | 0.10-0.25 | 1.00 | |||||||||

| TP304 | S30400 | 0.03 | 2 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | |||||||||||

| TP304L | S30403 | 0.08 | 2 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-13.0 | |||||||||||

| TP304H | S30409 | 0.035 | 2 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | |||||||||||

| S30415 | 0.04-0.10 | 0.8 | 0.045 | 0.030 | 1.00 | 18.0-19.0 | 9.0-10.0 | 0.12-0.18 | 0.03-0.08 | ||||||||||

| TP304N | S30451 | 0.04-0.06 | 2 | 0.045 | 0.030 | 2.00 | 18.0-20.0 | 8.0-18.0 | 0.10-0.16 | ||||||||||

| TP304LN | S30453 | 0.08 | 2 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | 0.10-0.16 | ||||||||||

| S30600 | 0.035 | 2 | 0.02 | 0.02 | 3.7-4.3 | 17.0-18.5 | 14.0-15.5 | 0.20 | 0.50 max | ||||||||||

| S30615 | 0.018 | 2 | 0.030 | 0.030 | 3.2-4.0 | 17.0-19.5 | 13.5-16.0 | 0.80-0.15 | |||||||||||

| S30815 | 0.16-0.24 | 0.8 | 0.045 | 0.030 | 1.40-2.00 | 20.0-22.0 | 10.0-12.0 | 0.14-0.20 | 0.03-0.08 | ||||||||||

| TP309S | S30908 | 0.05-0.10 | 2.00 | 0.045 | 0.030 | 2.00 | 22.0-24.0 | 12.0-15.0 | 0.75 | ||||||||||

| TP309H | S30909 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-15.0 | |||||||||||

| TP309Cb | S30940 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10*C min, 1.10 max | |||||||||

| TP309HCb | S30941 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10*C min, 1.10 max | |||||||||

| S31002 | 0.04-0.10 | 2.00 | 0.020 | 0.015 | 1.00 | 24.0--26.0 | 19.0-22.0 | 0.10 | 0.1 | ||||||||||

| TP310S | S31008 | 0.015 | 2.00 | 0.045 | 0.030 | 0.15 | 24.0-26.0 | 19.0-22.0 | 0.75 | ||||||||||

| TP310H | S31009 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0-26.0 | 19.0-22.0 | W2.0-4.0 | ||||||||||

| S31035 | 0.04-0.10 | 0.6 | 0.030 | 0.015 | 1.00 | 21.5-23.5 | 23.5-26.5 | Co1.0-2.0 | |||||||||||

| Grade | UNS -Designation | Carbon | Manga nese | Phos phorus | Sulfur | Slicon | Chrom-ium | Nickel | Molyb-denum | Tita-nlum | Colum-bium | Tanta-lum, max | Nitro-genC | Vana-dium | Copper | Cerium | Boron | Alum-inum | Other |

| TP310Cb | S31040 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10*C min, 1.10 max | |||||||||

| TP310HCb | S31041 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10*C min, 1.10 max | |||||||||

| S31050 | 0.025 | 2.00 | 0.02 | 0.015 | 0.4 | 24.0-26.0 | 20.5-23.5 | 0.75 | |||||||||||

| S31254 | 0.02 | 1.00 | 0.03 | 0.01 | 0.8 | 19.5-20.5 | 17.5-18.5 | 1.6-2.6 | |||||||||||

| S31272 | 0.08-012 | 1.5-2.00 | 0.03 | 0.015 | 0.25-0.75 | 14.0-16.0 | 14.0--16.0 | 6.0--6.5 | 0.30-0.60 | ||||||||||

| S31277 | 0.02 | 3.00 | 0.03 | 0.01 | 0.5 | 20.5-23.0 | 26.0-28.0 | 1.00-1.40 | |||||||||||

| TP316 | S31 600 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0 | 6.5-8.0 | ||||||||||

| TP316L | S31 603 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0--14.0 | 2.00-3.00 | ||||||||||

| TP316H | S31609 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.00-3.00 | ||||||||||

| TP316Ti | S31 635 | 0.08 | 2.00 | 0.045 | 0.03 | 0.75 | 16.0-18.0 | 11.0-15.0 | 2.00-3.00 | 5X(C+N)-0.70 | |||||||||

| TP316LN | S31 651 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-15.0 | 2.00-3.00 | ||||||||||

| TP317 | S31 653 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 13.5-17.5 | 2.00-3.00 | ||||||||||

| TP317L | S31700 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0-20.0 | 14.5-17.5 | 2.00-3.00 | ||||||||||

| S31 703 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0-20.0 | 14.5-16.5 | 3.0-4.0 | |||||||||||

| S31725 | 0.03 | 2.00 | 0.04 | 0.03 | 1.00 | 18.0-20.0 | 24.0-26.0 | 3.0-4.0 | |||||||||||

| S31726 | 0.03 | 2.00 | 0.040" | 0.03 | 1.00 | 17.0-20.0 | 9.0-12.0 | 4.0-5.0 | |||||||||||

| S31727 | 0.03 | 1.00 | 0.03 | 0.03 | 1.00 | 17.5-19.0 | 9.0-12.0 | 4.0-5.0 | |||||||||||

| S32053 | 0.03 | 1.00 | 0.03 | 0.01 | 1.00 | 22.0-24.0 | 19.0-22.0 | 3.8-4.5 | 0.025 | ||||||||||

| TP321 | S32100 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 21.0-23.0 | 5.0-6.0 | G | |||||||||

| TP321H | S32109 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 31.0-33.0 | H | ||||||||||

| S32615 | 0.07 | 2.00 | 0.045 | 0.03 | 48-6.0 | 16.5-19.5 | 16.0-18.0 | 0.30-1.50 | |||||||||||

| S33228 | 0.02 | 2.0-4.0 | 0.03 | 0.005 | 0.5 | 24.0-25.0 | 9.0-13.0 | 7.0-8.0 | |||||||||||

| S34565 | 0.04-0.08 | 1.00 | 0.02 | 0.015 | 0.3 | 26.0-28.0 | 9.0-13.0 | ||||||||||||

| S34700 | 0.03 | 5.0-7.0 | 0.03 | 0.01 | 1.00 | 23.0-25.0 | 4.0-5.0 | ||||||||||||

| T347 | S32654 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | |||||||||||||

| TP347H | S34709 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 |

| Grade | UNS -Designation | Carbon | Manga- nese | Phos- phorus | Sulfur | Silicon | Chrom- ium | Nickel | Molyb- denum | Tita- nium | Colum- bium | Tanta- lum, max | Nitro- genC | Vana- dium | Copper | Cerium | Boron | Alum- inum | Other |

| TP347LN | S34751 | 0.005- 0.020 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0- 19.0 | 9.0- 13.0 | 0.20-0.50 | 0.06-0.10 | |||||||||

| TP348 | S34800 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-13.0 | 0.10 | 0.15-0.60 | |||||||||

| TP348H | S34809 | 0.04- 0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0- 19.0 | 9.0- 13.0 | 0.10 | ||||||||||

| S35045 | 0.06- 0.10 | 1.50 | 0.015 | 1.00 | 25.0-29.0 | 32.0- 37.0 | 0.15-0.60 | 0.75 | 0.15-0.60 | ||||||||||

| S35315 | 0.04- 0.08 | 2.00 | 0.040 | 0.030 | 1.20-2.00 | 24.0-26.0 | 34.0- 36.0 | 0.12-0.18 | 0.03-0.08 | ||||||||||

| TPXM-15 | S38100 | 0.08 | 2.00 | 0.030 | 0.030 | 1.50-2.50 | 17.0-19.0 | 17.5-18.5 | 0.03-0.08 | 0.15-0.60 | |||||||||

| S38815 | 0.030 | 2.00 | 0.040 | 0.030 | 5.5-6.5 | 13.0-15.0 | 15.0-17.0 | 0.75-1.50 | 0.75-1.50 | 0.30 | |||||||||

| 0.030 | 2.00 | 0.040 | 0.020 | 5.5- 6.5 | 13.0- 15.0 | 15.0- 17.0 | 0.75- 1.50 | ||||||||||||

| Aloy 20 | N08020 | 0.07 | 2.00 | 0.045 | 0.035 | 1.00 | 19.0-21.0 | 32.0- 38.0 | 2.0- 3.0 | 3.0-4.0 | |||||||||

| N08367 | 0.030 | 2.00 | 0.040 | 0.030 | 1.00 | 20.0-22.0 | 23.5-25.5 | 6.0-7.0 | 0.18-0.25 | 0.75 | |||||||||

| 800 | N08800 | 0.10 | 1.50 | 0.045 | 0.015 | 19.0-23.0 | 30.0-35.0 | 0.15-0.60 | 0.75 | 0.15-0.60 | Fe39.5 min | ||||||||

| 800H | N08810 | 0.60-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | 0.15-0.60 | 0.75 | 0.15-0.60 | Fe39.5 min | |||||||

| N08811 | 0.05-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | 0.15-0.60 | 0.75 | 0.15-0.60 | Fe39.5 min | ||||||||

| N08904 | 0.020 | 2.00 | 0.040 | 0.030 | 1.00 | 19.0-23.0 | 23.0-28.0 | 4.0- 5.0 | 0.1 | 1.00-2.00 | |||||||||

| N08925 | 0.020 | 1.00 | 0.040 | 0.030 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | 0.10-0.20 | 0.80-1.50 | |||||||||

| N08926 | 0.020 | 2.00 | 0.030 | 0.010 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | 0.15-0.25 | 0.50-1.50 |

A. New designation established in accordance with Practice E527 and SAE J1086.

B. Maximun, unless otherwise indicated. Where eliyses appear in this table, there is no requiement and analysis for the element ned not be demined or reported.

C. The method of analysis for nitrogen shall be a matter of agreement between the purchaser and manufacturer.

D. For small diameter or thin walls or both, where mary drawing pa ses are required, a carbon maximum of 0.040% is necessay in gades TP304L andTP316. Small outside diameter tubes are defined as those less than 0.5000 in.[12.7 mm) in outside diameter and light wall tubes as those less than 0o49 in. [1.20 mm) in average wall thickness (0.044 in 1.10mm) in mininum wal thickness.

E. For welded TP316, TP316N, TP316LN, and TP316H pipe, the nickel range shall be 10.0-14.0 %.

F. For welded pipe, the phosphorus maximum shall be 0.045%.

G. Ti5×(C+N) min, 0.70 max.

H. Ti4×(C+N) min, 0.60 max.

I. The columbium content shall be not less than ten times the carbon content and not more than 1.00 %.

J. The columbium content shall be not less than eight times the carbon content and not more than 1.0 %.

K. Grade S34751 shall have a columbium (niobium) content of not less than 15 times the carbon content.

L. Iron shall be determined arithmetically by difference of 100 minus the sum of the other specified elements.

M. (Al+ Ti) 0.85-1.20.

N. Columbium (Nb)+ Tantalum =8 x Carbon min,1.00 max.

KIDY is a service-oriented enterprise, and produces different types of steel pipes, with regular steel grades such as TP304/TP304L, TP321, TP316/TP316L, etc. Regular medium specifications are readily available in stock for quick delivery, and individual lengths can be customized according to requirements. Special requirements are also available for customization.

Austenitic stainless steel pipe refers to stainless steel with austenitic structure at high temperature and room temperature. When the steel contains about 18% Cr, 8%~10% Ni, and about 0.1% C, it has a stable austenite structure.

Austenitic chromium nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr Ni series steel developed by increasing Cr and Ni content and adding elements such as Mo, Cu, Si, Nb, Ti, etc. on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is not possible to strengthen it through phase transformation, and can only be strengthened through cold working. For example, adding elements such as S, Ca, Se, Te, etc., will result in good machinability.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.