ASTM A182 ASME B16.5 pipe flanges and flange fittings are forged using the forging process, with a specification of 1/2 "-24" and a pressure rating of 150LB-2500LB; Suitable for liquid, particle, and gas transportation pipelines, such as chemical, refining, boilers, electricity, food, and other fields.

| Table 1A List of Material Specifications | |||||

| Material Group | Nominal Designation | Pressure- Temper nature Rating Table | Applicable ASTM Specifications [Note (1)] | ||

| Forgings | Castings | Plates | |||

| 1.1 | C-SI | 2-1.1 | A105 | A216 Gr. WCB | A515 Gr.70 |

| C-Mn-Si | 2-1.1 | A350 Gr. LF2 | ... | A516 Gr. 70 | |

| C-Mn-Si | 2-1.1 | ... | ... | A537 CL 1 | |

| C-Mn-Si-V | 2-1.1 | A350 Gr. LF6 CI. 1 | ... | ... | |

| 3½ Ni | 2-1.1 | A350 Gr.LF3 | ... | ... | |

| 1.2 | C-Mn-Si | 2-1.2 | ... | A216 G. WCC | ... |

| C-Mn-Si | 2-1.2 | ... | A352 Gr.LCC | ... | |

| C-Mn-Si-V | 2-1.2 | A350 Gr. LF6 CI. 2 | ... | ... | |

| 2½N | 2-1.2 | ... | A352 Gr.LC2 | A203 Gr.B | |

| 3½NI | 2-1.2 | ... | A352 Gr.LC3 | A203 Gr. E | |

| 1.3 | C-Si | 2-1.3 | ... | A352 G. LCB | A515 Gr. 65 |

| C-Mn-Si | 2-1.3 | ... | ... | A516 Gr 65 | |

| 2½N | 2-1.3 | ... | ... | A203 Gr. A | |

| 3½NI | 2-1.3 | ... | ... | A203 Gr.D | |

| C-½Mo | 2-1.3 | ... | A217 Gr.WC1 | ... | |

| C-½Mo | 2-1.3 | ... | A352 Gr. LC1 | ... | |

| 1.4 | C-Si | 2-1.4 | ... | ... | A515 Gr.60 |

| C-Mn-Si | 2-1.4 | A350 Gr. LF1 CI.1 | ... | A516 Gr.60 | |

| 1.5 | C-½Mo | 2-1.5 | A182 Gr. F1 | ... | A204 Gr.A |

| C-½Mo | 2-1.5 | ... | ... | A204 Gr.B | |

| 1.7 | ½C1-½Mo | 2-1.7 | A182 Gr.F2 | A217 Gr.WNC4 | ... |

| Ni-½Cr-½Mo | 2-1.7 | ... | |||

| ¾Ni-¾Cr-1Mo | 2-1.7 | A217 Gr. WC5 | ... | ||

| 1.9 | 1¼Cr-½Mo | 2-1.9 | ... | A217 Gr. WC6 | ... |

| 1¼Cr-½Mo-Si | 2-1.9 | A182 Gr.F11 CL.2 | ... | A387 Gr. 11 CL 2 | |

| 1.10 | 2¼C-1Mo | 2-1.10 | A182 Gr. F22 CI. 3 | A 217Gr WC9 | A387 Gr. 22 CL 2 |

| 1.11 | C-¼Mo | 2-1.11 | ... | ... | A204 G.C |

| 1.13 | 5Cr-½Mo | 2-1.13 | A182 Gr.F5a | A217 Gr.C5 | ... |

| 1.14 | 9Cr-1M0 | 2-1.14 | A182 Gr.F9 | A217 Gr.C12 | ... |

| 1.15 | 9Cr-1MO-V | 2-1.15 | A182 Gr. F91 | A217 Gr. C12A | A387 Gr. 91 CL 2 |

| 1.17 | 1Cr-½Mo | 2-1.17 | A182 Gr. F12 CL. 2 | ... | ... |

| 5Cr-½Mo | 2-1.17 | A182 Gr. F5 | ... | ... | |

| 1.18 | 9Cr-2W-V | 2-1.18 | A182 Gr. F92 | ... | ... |

| 2.1 | 18Cr-8Ni | 2-2.1 | A182 Gr. F304 | A351 G.CF3 | A240 Gr. 304 |

| 18Cr-8Ni | 2-2.1 | A182 Gr. F304H | A351 G. CF8 | A240 Gr.304H | |

| 2.2 | 16Cr-12Ni-2Mo | 2-2.2 | A182 Gr.F316 | A351 Gr.CF3M | A240 Gr.316 |

| 16Cr-12Ni-2Mo | 2-2.2 | A182 Gr. F316H | A351 Gr. CF8M | A240 Gr. 316H | |

| 18Ci-13Ni-3Mo | 2-2.2 | A182 Gr. F317 | ... | A240 Gr.317 | |

| 19Cr-10Ni-3Mo | 2-2.2 | A351 Gr.CG8M | ... | ||

| 2.3 | 18Cr-8Ni 16Cr-12Ni-2Mo | 2-2.3 2-2.3 | A182 Gr. F304L A182 Gr. F316L | ... | A240 Gr. 304L A240 Gr 316L |

| 18Cr-13Ni-3Mo | 2-2.3 | A182 Gr F317L | ... | ... | |

| Table 1A List of Material Specifications(Cont'd) | |||||

| Material Group | Nominal Designation | Pressure- Temperature Rating Table | Applicable ASTM Specifications [Note (1)] | ||

| Forgings | Castings | Plates | |||

| 2.4 | 18Cr-10Ni-TI | 2-2.4 | A182 Gr.F321 | ... | A240 Gr.321 |

| 18Cr-10Ni-Ti | 2-2.4 | A182 Gr.F321H | ... | A240 Gr.321H | |

| 2.5 | 18Cr-10NI-Cb | 2-2.5 | A182 Gr.F347 | ... | A240 Gr.347 |

| 18Cr-10Ni-Cb | 2-2.5 | A182 Gr.F347H | ... | A240 Gr.347H | |

| 18Cr-10NI-Cb | 2-2.5 | A182 Gr.F348 | ... | A240 Gr.348 | |

| 18Cr-10Ni-Cb | 2-2.5 | A182 Gr.F348H | ... | A240 Gr.348H | |

| 2.6 | 23Cr-12Ni | 2-2.6 | ... | ... | A240 Gr.309H |

| 2.7 | 25Cr-20Ni | 2-2.7 | A182 Gr.F310 | ... | A240 Gr.310H |

| 2.8 | 20Cr-18Ni-6Mo | 2-2.8 | A182 Gr.F44 | A 351 Gr.CK3MCuN | A 351 Gr.CK3MCuN A240 Gr.S31254 |

| 22Cr-5NI-3Mo-N | 2-2.8 | A182 Gr.F51 | ... | A240 Gr.S31803 | |

| 25Cr-7Ni-4Mo-N | 2-2.8 | A182 Gr.F53 | ... | A240 Gr.S32750 | |

| 24Cr-10Ni-4Mo-V | 2-2.8 | ... | A351 Gr.CEBMN | ... | |

| 25Cr-5Ni-2Mo-3Cu | 2-2.8 | ... | A995 Gr.CD4MCu | ... | |

| 25Cr-7Ni-3.5Mo-W-Cb | 2-2.8 | ... | A995 Gr.CD3MWOuN | ... | |

| 25Cr-7.5Ni-3.5Mo-N-Cu-W | 2-2.8 | A182 Gr.F55 | ... | A240 Gr.S32760 | |

| 2.9 | 23Cr-12NI | 2-2.9 | ... | ... | A240 Gr.309S |

| 25Cr-12Ni | 2-2.9 | ... | ... | A240 Gr.310S | |

| 2.10 | 25Cr-12NI | 2-2.10 | ... | A351 Gr. CHB | ... |

| 25Cr-12Ni | 2-2.10 | ... | A351 Gr. CH20 | ... | |

| 2.11 | 18Cr-10NI-Cb | 2-2.11 | ... | A351 G. CFBC | ... |

| 2.12 | 25Cr-20NI | 2-2.12 | ... | A351 Gr.CK20 | ... |

| 3.1 | 35Ni-35Fe-20Cr-Cb | 2-3.1 | B462 Gr.N08020 | ... | B463 Gr.N08020 |

| 3.2 | 99.ONI | 2-3.2 | B564 Gr.N02200 | ... | B162 Gr.N02200 |

| 3.3 | 99.ONi-Low C | 2-3.3 | ... | ... | B162 GL.N02201 |

| 3.4 | 67Ni-30Cu | 2-3.4 | B564 Gr.N04400 | ... | B127 G.N04400 |

| 3.5 | 72Ni-15Cr-8Fe | 2-3.5 | B564 Gr.N06600 | ... | B168 Gr.N06600 |

| 3.6 | 33Ni-42Fe-21Cr | 2-3.6 | B564 Gr.N08800 | ... | B409 Gr.N08800 |

| 3.7 | 65Ni-28Mo-2Fe | 2-3.7 | B462 Gr.N10665 | ... | B333 G.N10665 |

| 64Ni-29.5Mo-2Cr-2Fe-Mn-W | 2-3.7 | B462 Gr.N10675 | ... | B333 Gr.N10675 | |

| 3.8 | 54NI-16Mo-15Cr | 2-3.8 | B462 Gr.N10276 | ... | B575 Gr.N10276 |

| 60Ni-22Cr-9Mo-3.5Cb | 2-3.8 | B564 Gr.N06625 | ... | B443 Gr.N06625 | |

| 62Ni-28Mo-5Fe | 2-3.8 | ... | ... | B333 Gr.N10001 | |

| 70Ni-16Mo-7Cr-5Fe | 2-3.8 | ... | ... | B434 Gr.N10003 | |

| 61Ni-16Mo-16Cr | 2-3.8 | ... | ... | B575 Gr.N06455 | |

| 42Ni-21.5Cr-3MMo-2.3Cu | 2-3.8 | B564 Gr.N08825 | ... | B424 Gr.N08825 | |

| 55Ni-21Cr-13.5Mo | 2-3.8 | B462 Gr.N06022 | ... | B575 Gr.N06022 | |

| 55NI-23Cr-16Mo-1.6Cu | 2-3.8 | B462 Gr.N06200 | ... | B575 Gr.N06200 | |

| 3.9 | 47NI-22Cr-9Mo-18Fe | 2-3.9 | ... | ... | B435 Gr.N06002 |

| 21Ni-30Fe-22Cr-18Co-3Mo-3W | 2-3.9 | B572 Gr.R30556 | ... | B435 Gr.R30556 | |

| 3.10 | 25Ni-47Fe-21Cr-5Mo | 2-3.10 | ... | ... | B599 Gr.N08700 |

| Table 1A List of Material Specifications (Cont'd) | |||||

| Material Group | Nominal Designation | Pressure-Temperature Rating Table | Applicable ASTM Specifications [Note(1)] | ||

| Forgings | Castings | Plates | |||

| 3.11 | 44Fe-25Ni-21Cr-Mo | 2-3.11 | A479 Gr. N08904 | ... | A240 Gr.N08904 |

| 3.12 | 26Ni-43Fe-22Cr-5Mo | 2-3.12 | ... | ... | B620 Gr.N08320 |

| 47Ni-22Cr-20Fe-7Mo | 2-3.12 | ... | ... | B582 Gr.N06985 | |

| 46Fe-24Ni-21Cr-6Mo-Cu-N | 2-3.12 | B462 Gr.N08367 | A351 Gr.CN3MN | B688 Gr.N08367 | |

| 3.13 | 49Ni-25Cr-18Fe-6Mo | 2-3.13 | ... | ... | B582 Gr. N06975 |

| Ni-Fe-Cr-Mo-Cu-Low C | 2-3.13 | B564 Gr.N08031 | ... | B625 Gr.N08031 | |

| 3.14 | 47Ni-22Cr-19Fe-6Mo | 2-3.14 | ... | B582 Gr.N06007 | |

| 40Ni-29Cr-15Fe-5Mo | 2-3.14 | B462 Gr.N06030 | ... | B582 Gr.N06030 | |

| 58Ni-33Cr-8Mo | 2-3.14 | B462 Gr.N06035 | ... | B575 Gr.N06035 | |

| 3.15 | 42Ni-42Fe-21Cr | 2-3.15 | B564 Gr.N08810 | ... | B409 Gr.N08810 |

| 3.16 | 35Ni-19Cr-1 ¼Si | 2-3.16 | B511 Gr.N08330 | ... | B536 Gr.N08330 |

| 3.17 | 29NI-20.5Cr-3.5Cu-2.5Mo | 2-3.17 | ... | A351 Gr.CN7M | ... |

| 3.19 | 57Ni-22CR-14W-2Mo-La | 2-3.19 | B564 Gr.N06230 | ... | B435 Gr. N06230 |

GENERAL NOTES:

(a) For temperature limitations, see notes in ables ll-2-1.1 through l-2-3.17 of Mandatory Appendix ll.

(b) Plate materials are listed only for use as blind flanges and reducing flanges without hubs (see para. 5.1). Additional plate materals listed in ASME B16.34 may also be used with coresponding B16.34, Standard Class ratings.

NOTE:

(1) ASlE Boller and Pressure Vessel Code, Section ll materials may also be used, provided the requrements of the ASME specification are identical to or more stringent than the corresponding ASTM specification for the Grade, Class, or Type listed.

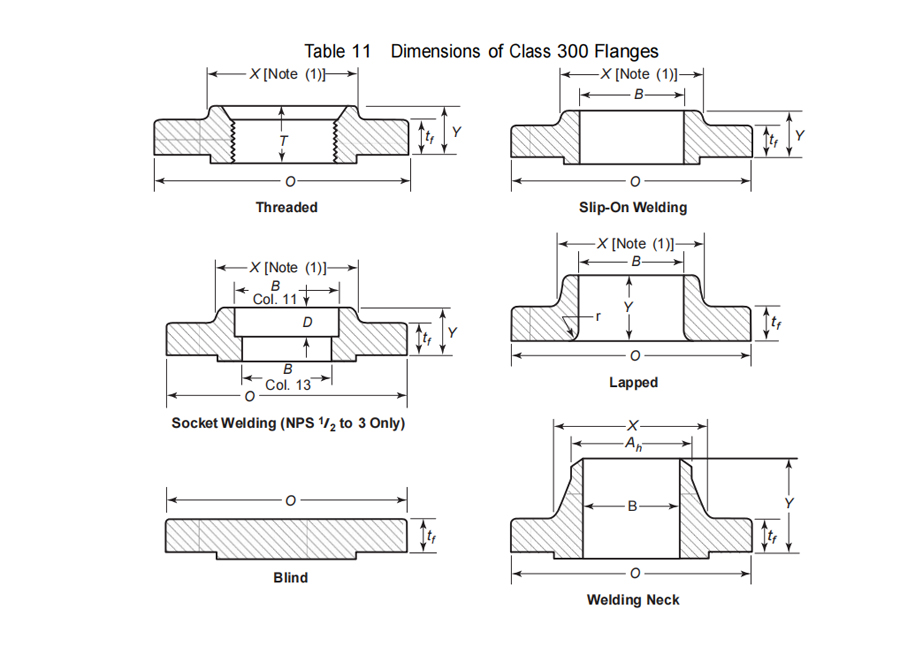

| Table 11 Dimensions of Class 300 Flanges (Cont'd) | |||||||||||||||

| Length Through Hub | Bore | ||||||||||||||

Nominal Pipe of Size | Outside Diameter of Flange | Minimum Thickness of Flange, tf | Minimum Thickness Lap Joint | Diameter of Hub | Hub Diameter Beginning of Chamfer Welding, Welding, SlipOn/Neck, Ah | Threaded/ Slip-On/ Socket Welding | Lapped | Welding Neck | Minimum Thread Length Threaded, T | Minimum Slip-On/Socket Welding | Minimum Lapped | Welding Neck/Socket Welding | Corner Radius of Bore of Lapped Flange and Pipe | Minimum Counter-bore Threaded Flange, | Depth of Socket |

| NPS | O | [Notes(2)-(4)] | tf | X | [Note (4)] | Y | Y | Y | [Note(5)] | B | B | [Note(6)] | r | Q | D |

| ½ | 95 | 12.7 | 14.3 | 38 | 21.3 | 21 | 22 | 51 | 16 | 22.2 | 22.9 | 15.8 | 3 | 23.6 | 10 |

| ¾ | 115 | 14.3 | 15.9 | 48 | 26.7 | 24 | 25 | 56 | 16 | 27.7 | 28.2 | 20.9 | 3 | 29.0 | 11 |

| 1 | 125 | 15.9 | 17.5 | 54 | 33.4 | 25 | 27 | 60 | 18 | 34.5 | 34.9 | 26.6 | 3 | 35.8 | 13 |

| 1¼ | 135 | 17.5 | 19.1 | 64 | 42.2 | 25 | 27 | 64 | 21 | 43.2 | 43.7 | 35.1 | 5 | 44.4 | 14 |

| 1½ | 155 | 19.1 | 20.7 | 70 | 48.3 | 29 | 30 | 67 | 23 | 49.5 | 50.0 | 40.9 | 6 | 50.3 | 16 |

| 2 | 165 | 20.7 | 22.3 | 84 | 60.3 | 32 | 33 | 68 | 29 | 61.9 | 62.5 | 52.5 | 8 | 63.5 | 17 |

| 2½ | 190 | 23.9 | 25.4 | 100 | 73.0 | 37 | 38 | 75 | 32 | 74.6 | 75.4 | 62.7 | 8 | 76.2 | 19 |

| 3 | 210 | 27.0 | 28.6 | 117 | 88.9 | 41 | 43 | 78 | 32 | 90.7 | 91.4 | 77.9 | 10 | 92.2 | 21 |

| 3½ | 230 | 28.6 | 30.2 | 133 | 101.6 | 43 | 44 | 79 | 37 | 103.4 | 104.1 | 90.1 | 10 | 104.9 | ... |

| 4 | 255 | 30.2 | 31.8 | 146 | 114.3 | 46 | 48 | 84 | 37 | 116.1 | 116.8 | 102.3 | 11 | 117.6 | ... |

| 5 | 280 | 33.4 | 35.0 | 178 | 141.3 | 49 | 51 | 97 | 43 | 143.8 | 144.4 | 128.2 | 11 | 144.4 | ... |

| 6 | 320 | 35.0 | 36.6 | 206 | 168.3 | 51 | 52 | 97 | 47 | 170.7 | 171.4 | 154.1 | 13 | 171.4 | ... |

| 8 | 380 | 39.7 | 41.3 | 260 | 219.1 | 60 | 62 | 110 | 51 | 221.5 | 222.2 | 202.7 | 13 | 222.2 | ... |

| 10 | 445 | 46.1 | 47.7 | 321 | 273.0 | 65 | 95 | 116 | 56 | 276.2 | 277.4 | 254.6 | 13 | 276.2 | ... |

| 12 | 520 | 49.3 | 50.8 | 375 | 323.8 | 71 | 102 | 129 | 61 | 327.0 | 328.2 | 304.8 | 13 | 328.6 | ... |

| 14 | 585 | 52.4 | 54.0 | 425 | 355.6 | 75 | 111 | 141 | 64 | 359.2 | 360.2 | Note(7) | 13 | 360.4 | ... |

| 16 | 650 | 55.6 | 57.2 | 483 | 406.4 | 81 | 121 | 144 | 69 | 410.5 | 411.2 | Note(7) | 13 | 411.2 | ... |

| 18 | 710 | 58.8 | 60.4 | 533 | 457.0 | 87 | 130 | 157 | 70 | 461.8 | 462.3 | Note(7) | 13 | 462.0 | ... |

| 20 | 775 | 62.0 | 63.5 | 587 | 508.0 | 94 | 140 | 160 | 74 | 513.1 | 514.4 | Note(7) | 13 | 512.8 | ... |

| 24 | 915 | 68.3 | 69.9 | 702 | 610.0 | 105 | 152 | 167 | 83 | 616.0 | 616.0 | Note (7) | 13 | 614.4 | ... |

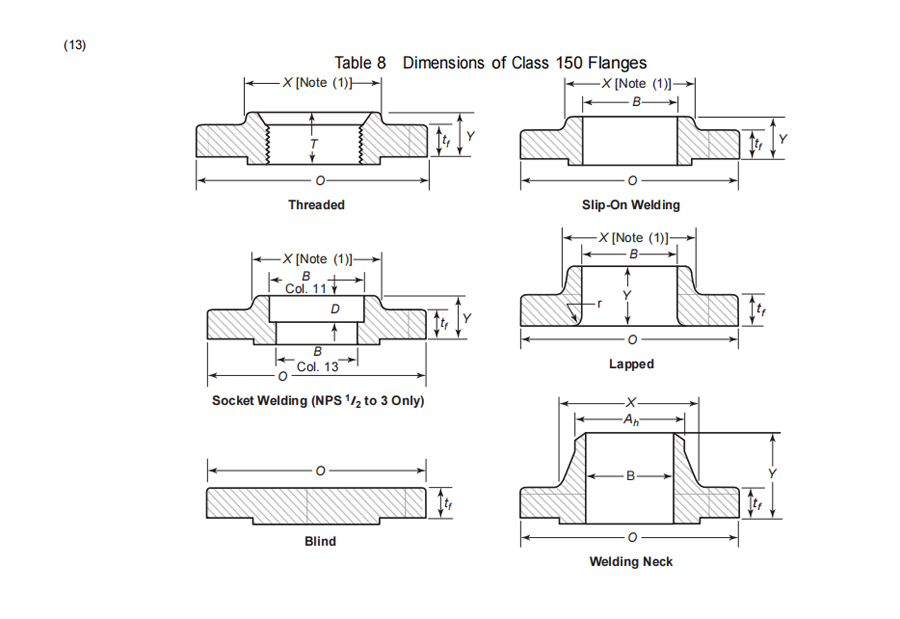

| Table 8 Dimensions of Class 150Flanges (Cont'd) | ||||||||||||||

| Length Through Hub | Bore | |||||||||||||

| Nominal Pipe of Size | Outside Diameter of Flange | Minimum Thickness of Flange, tf | Minimum Thickness Lap Joint | Diameter of Hub | Hub Diameter Beginning of Chamfer Welding, Welding, Slip-On/Neck, Ah | Threaded/ Slip-On/ Socket Welding | Lapped | Welding Neck | Minimum Thread Length Threaded, T | Minimum Slip-On/Socket Welding | Minimum Lapped | Welding Neck/Socket Welding, | Corner Radius of Bore of Lapped Flange and Pipe | Depth of Socket |

| NPS | O | [Notes(2)-(4)] | tf | X | [Note(5)] | Y | Y | Y | [Note(6)] | B | B | [Note(7)] | r | D |

| ½ | 90 | 9.6 | 11.2 | 30 | 21.3 | 14 | 16 | 46 | 16 | 22.2 | 22.9 | f5.8 | 3 | 10 |

| ¾ | 100 | 11.2 | 12.7 | 38 | 26.7 | 14 | 16 | 51 | 16 | 27.7 | 28.2 | 20.9 | 3 | 11 |

| 1 | 110 | 12.7 | 14.3 | 49 | 33.4 | 16 | 17 | 54 | 17 | 34.5 | 34.9 | 26.6 | 3 | 13 |

| 1¼ | 115 | 14.3 | 15.9 | 59 | 42.2 | 19 | 21 | 56 | 21 | 43.2 | 43.7 | 35.1 | 5 | 14 |

| 1½ | 125 | 15.9 | 17.5 | 65 | 48.3 | 21 | 22 | 60 | 22 | 49.5 | 50.0 | 40.9 | 6 | 16 |

| 2 | 150 | 17.5 | 19.1 | 78 | 60.3 | 24 | 25 | 62 | 25 | 61.9 | 62.5 | 52.5 | 8 | 17 |

| 2½ | 180 | 20.7 | 22.3 | 90 | 73.0 | 27 | 29 | 68 | 29 | 74.6 | 75.4 | 62.7 | 8 | 19 |

| 3 | 190 | 22.3 | 23.9 | 108 | 88.9 | 29 | 30 | 68 | 30 | 90.7 | 91.4 | 77.9 | 10 | 21 |

| 3½ | 215 | 22.3 | 23.9 | 122 | 101.6 | 30 | 32 | 70 | 32 | 103.4 | 104.1 | 90.1 | 10 | ... |

| 4 | 230 | 22.3 | 23.9 | 135 | 114.3 | 32 | 33 | 75 | 33 | 116.1 | 116.8 | 102.3 | 11 | ... |

| 5 | 255 | 22.3 | 23.9 | 164 | 141.3 | 35 | 36 | 87 | 36 | 143.8 | 144.4 | 128.2 | 11 | ... |

| 6 | 280 | 23.9 | 25.4 | 192 | 168.3 | 38 | 40 | 87 | 40 | 170.7 | 171.4 | 154.1 | 13 | ... |

| 8 | 345 | 27.0 | 28.6 | 246 | 219.1 | 43 | 44 | 100 | 44 | 221.5 | 222.2 | 202.7 | 13 | ... |

| 10 | 405 | 28.6 | 30.2 | 305 | 273.0 | 48 | 49 | 100 | 49 | 276.2 | 277.4 | 254.6 | 13 | ... |

| 12 | 485 | 30.2 | 31.8 | 365 | 323.8 | 54 | 56 | 113 | 56 | 327.0 | 328.2 | 304.8 | 13 | ... |

| 14 | 535 | 33.4 | 35.0 | 400 | 355.6 | 56 | 79 | 125 | 57 | 359.2 | 360.2 | Note(8) | 13 | ... |

| 16 | 595 | 35.0 | 36.6 | 457 | 406.4 | 62 | 87 | 125 | 64 | 410.5 | 411.2 | Note(8) | 13 | ... |

| 18 | 635 | 38.1 | 39.7 | 505 | 457.0 | 67 | 97 | 138 | 68 | 461.8 | 462.3 | Note(8) | 13 | ... |

| 20 | 700 | 41.3 | 42.9 | 559 | 508.0 | 71 | 103 | 143 | 73 | 513.1 | 514.4 | Note(8) | 13 | ... |

| 24 | 815 | 46.1 | 47.7 | 663 | 610.0 | 81 | 111 | 151 | 83 | 616.0 | 616.0 | Note(8) | 13 | ... |

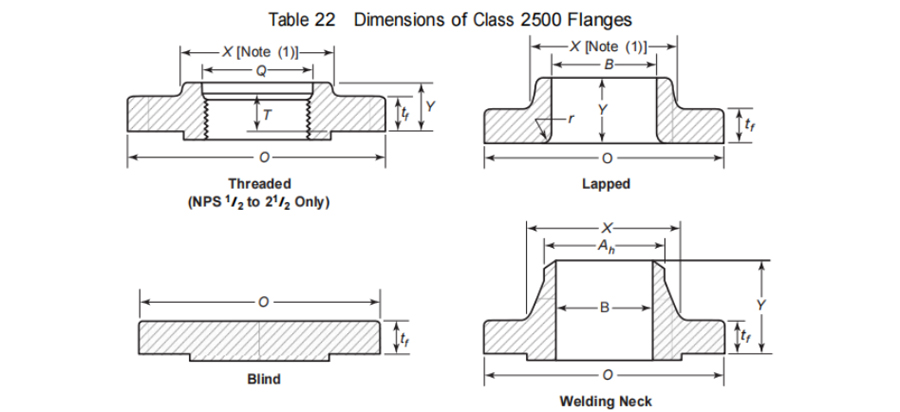

| Table 22 Dimensions of Class 2500 Flanges (Cont'd) | ||||||||||||

| Length Through Hub | Bore | |||||||||||

| Nominal Pipe of Size | Outside Diameter of Flange | Minimum Thickness of Flange | Diam. of Hub, | Hub Diam. Beginning of Chamfer Welding Neck, Ah | Threaded | Lapped | Welding Neck | Minimum Thread Length Threaded Flange, T | Min. Lapped | Welding Neck | Corner Bore Radius of Lapped Flange and Pipe | Minimum Counter bore Threaded Flange |

| NPS | O | tf | X | [Note(2)] | Y | Y | Y | [Note(3)] | B | B | r | Q |

| ½ | 135 | 30.2 | 43 | 21.3 | 40 | 40 | 73 | 29 | 22.9 | Note(4) | 3 | 23.6 |

| ¾ | 140 | 31.8 | 51 | 26.7 | 43 | 43 | 79 | 32 | 28.2 | Note(4) | 3 | 29.0 |

| 1 | 160 | 35.0 | 57 | 33.4 | 48 | 48 | 89 | 35 | 34.9 | Note(4) | 3 | 35.8 |

| 1¼ | 185 | 38.1 | 73 | 42.2 | 52 | 52 | 95 | 39 | 43.7 | Note(4) | 5 | 44.4 |

| 1½ | 205 | 44.5 | 79 | 48.3 | 60 | 60 | 111 | 45 | 50.0 | Note(4) | 6 | 50.6 |

| 2 | 235 | 50.9 | 95 | 60.3 | 70 | 70 | 127 | 51 | 62.5 | Note(4) | 8 | 63.5 |

| 2½ | 265 | 57.2 | 114 | 73.0 | 79 | 79 | 143 | 58 | 75.4 | Note(4) | 8 | 76.2 |

| 3 | 305 | 66.7 | 133 | 88.9 | ... | 92 | 168 | ... | 91.4 | Note(4) | 10 | ... |

| 4 | 355 | 76.2 | 165 | 114.3 | ... | 108 | 190 | ... | 116.8 | Note(4) | 11 | ... |

| 5 | 420 | 92.1 | 203 | 141.3 | ... | 130 | 229 | ... | 144.4 | Note(4) | 11 | ... |

| 6 | 485 | 108.0 | 235 | 168.3 | ... | 152 | 273 | ... | 171.4 | Note(4) | 13 | ... |

| 8 | 550 | 127.0 | 305 | 219.1 | ... | 178 | 318 | ... | 222.2 | Note(4) | 13 | ... |

| 10 | 675 | 165.1 | 375 | 273.0 | ... | 229 | 419 | ... | 277.4 | Note(4) | 13 | ... |

| 12 | 760 | 184.2 | 441 | 323.8 | ... | 254 | 464 | ... | 328.2 | Note(4) | 13 | ... |

KIDY is a service-oriented enterprise with a complete range of steel grades; Conventional steel grades F304/304L, F321, F316/316L, and other material specifications are available for long-term flange blanks for quick delivery. The packaging is in export wooden boxes, and special size requirements can be customized.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.