The forming of seamless stainless steel pipe is mainly completed through the following steps:Material preparation: Select the appropriate stainless steel material, and cut and straighten according to the requirements of the pipe.Heating: The stainless steel pipe is heated to a certain temperature, usually above 1100 ° C, to make it soft and plastic.Air cooling: Air cooling of the heated stainless steel pipe, so that it quickly cool and maintain shape.Forging: The use of special forging equipment, the heated and cooled stainless steel pipe into the equipment, and through mechanical force to forge it. This process causes the stainless steel pipe to gradually form the desired shape.Removal of residual stress: During the forging process, stainless steel pipes may produce residual stress, which needs to be de-stressed. The residual stress can be eliminated by annealing, precipitation hardening, etc.Rolling: According to the requirements of the pipeline, the formed stainless steel pipe is rolled to make it reach a more accurate size and shape.Temperature regulation: According to the different needs of stainless steel pipes, temperature regulation may be required during the molding process to ensure the quality and performance of the pipes.Surface treatment: After forming, the stainless steel pipe may have some irregular or jagged surface, which needs to be cut and polished to make its surface smooth.The above is the general forming process of seamless stainless steel pipe, and the specific production process and steps will be adjusted according to different requirements and products.

Stainless steel is an alloy material, mainly composed of iron, chromium, nickel and a small number of other elements. Among them, iron is the main base element, usually accounting for more than 70% of the total weight. Chromium is one of the most important alloying elements of stainless steel, usually between 10-20%, which can react with oxygen to form a dense chromium oxide film to prevent further oxidation of iron.

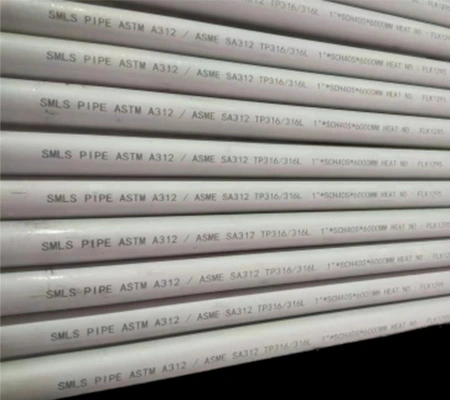

KIDY Steel Pipe manufacturing processes involve seamless and welded production methods. The seamless pipes are made by piercing a solid billet and rolling it into the desired shape, while the welded ones are made by welding two flat steel plates together.

The design of the pipes is critical in ensuring their performance and functionality. KIDY creates innovative designs that meet the specific needs of various industries and applications, optimizing for strength, flexibility, and durability.

KIDY uses advanced quality control techniques to ensure that the pipes adhere to strict manufacturing standards. The brand uses modern technologies such as ultrasonic testing, eddy current inspection, and hydrostatic testing to guarantee the quality of its products.

In addition to its top-quality manufacturing processes, KIDY Steel Pipe also pays close attention to sustainability. The brand's eco-friendly practices include recycling, waste reduction, and the use of clean energy. KIDY is committed to protecting the environment.

KIDY Steel Pipe provides numerous benefits to customers in various industries. Steel pipe is widely used for its high strength, durability, and versatility. KIDY's steel pipes are manufactured with the latest technology and quality control measures to meet the stringent requirements of different applications. The brand provides coatings that make their steel pipes resistant to rust and corrosion, which greatly extends the lifespan of the pipes. KIDY Steel Pipe is also cost-effective compared to other piping materials and has a low maintenance requirement. Moreover, its 100% recyclability makes it an eco-friendly option. These benefits, along with KIDY's commitment to sustainability and quality, make KIDY steel pipes the ideal choice for customers in various industries.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.