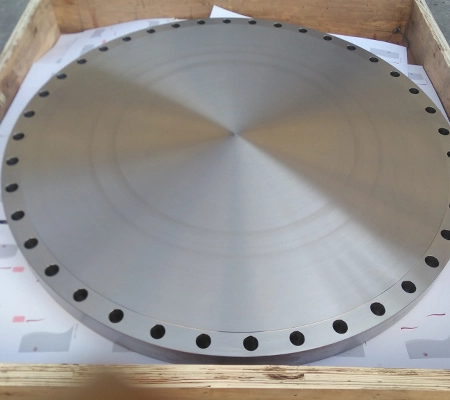

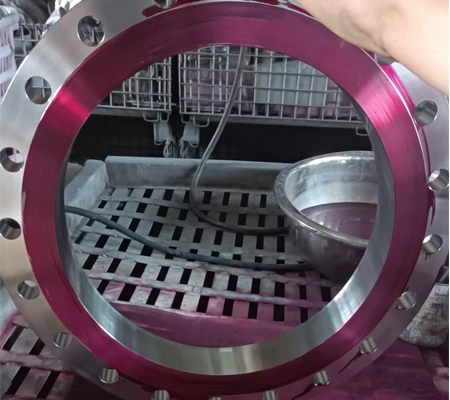

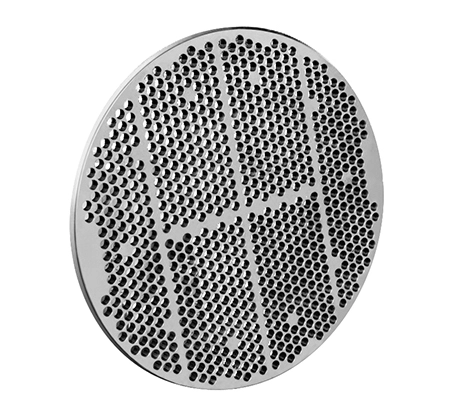

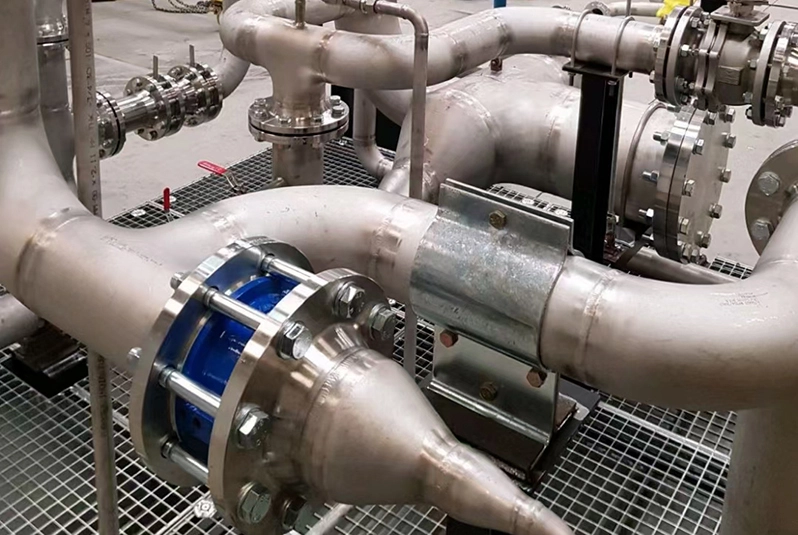

A steel flange is a mechanical device used in pipelines to connect pipes and provide support to valves, pumps, and other equipment. The steel flange consists of a flat surface with bolt holes, which are welded or screwed onto the end of the pipe. It provides a tight seal and prevents leakage by creating a continuous and permanent connection between the pipes. Steel flanges can be used in a range of industries, including oil and gas, chemical, petrochemical, and many others. They come in various sizes and types to suit different pipe sizes, temperatures, and pressure ratings. Steel flanges are manufactured using high-quality materials such as carbon steel, stainless steel, and alloy steel, making them durable and reliable for different applications.

Steel flanges play a significant role in pipeline systems by providing a secure, leak-proof connection between pipes and other pipeline components, such as valves, pumps, and vessels. They are widely used in a range of industries, including oil and gas, petrochemical, and many others.

KIDY Steel Flanges offer a range of steel flanges that are manufactured using high-quality materials like carbon steel, stainless steel, and alloy steel, ensuring that they can endure harsh conditions and last for a long time. Their flanges come in various sizes, types, and pressure ratings, making them suitable for many different applications. Furthermore, their flanges meet industry standards, ensuring that their performance will satisfy the expectations of many industries. KIDY steel flanges are easy to install and versatile, ensuring that pipeline systems are secure and reliable. Customers can rely on KIDY Steel Flanges to provide high-quality flanges that guarantee a tight seal and a long-lasting performance, regardless of the harsh conditions or pressures involved in their operations.

Material selection: KIDY selects high-quality materials such as carbon steel, stainless steel, and alloy steel, ensuring that the quality and durability of their steel flanges are not compromised.

Forging and machining: KIDY utilizes state-of-the-art forging and machining processes to create the precise dimensions required for different types of steel flanges.

Heat treatment: KIDY uses heat treatment procedures to enhance the strength and durability of steel flanges, ensuring that they can withstand various environments.

Quality control: KIDY conducts rigorous testing procedures and adheres to industry standards during the manufacturing process to ensure that their steel flanges meet the expectations of their customers.

The manufacturing of steel flanges must adhere to specific criteria to guarantee the highest degree of quality, performance, and safety. KIDY is dedicated to producing steel flanges that comply with numerous international standards while ensuring their products are of the highest quality. KIDY's Steel Flanges comply with relevant standards like ASME B16.5, ASME B16.47, DIN, JIS, and many more. This ensures that their steel flanges meet the required dimensions, thickness, pressure ratings, and temperature requirements for their intended applications. KIDY also follows quality control processes that align with ISO 9001:2015 and seeks to achieve industry certifications such as CE, API, and AD. As a result, customers of KIDY Steel Flanges can expect products that are tested and certified to perform to the expected standards, delivering superior performance and long-lasting durability, no matter the application.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.