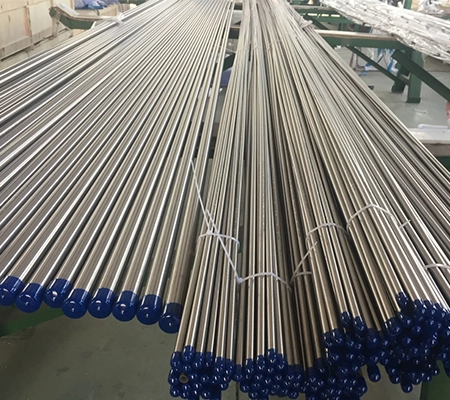

Stainless steel seamless pipes and tubes are very similar in terms of their composition, but they differ in their manufacturing process and intended use.Manufacturing Process: Seamless Pipes: Seamless pipes are manufactured using a piercing rod that creates a hollow tube by pushing it through a hot metal billet. This process ensures a smooth and even surface finish without any welded seams.

Seamless Tubes: Seamless tubes are also manufactured using the same piercing rod process, but they are typically smaller in diameter compared to pipes.Intended Use:Seamless Pipes: Seamless pipes are typically used for transporting fluids, such as water, oil, gas, or chemicals. They are widely used in industries like oil and gas, petrochemical, pharmaceutical, food processing, and automotive.Seamless Tubes: Seamless tubes are commonly used in applications where high precision is required, such as heat exchangers, boilers, condensers, instrumentation, and hydraulic systems.Strength and Durability:Seamless Pipes: Due to their larger diameter and thicker walls, seamless pipes are generally more robust and can withstand higher pressure levels. They are suitable for critical applications where strength and durability are essential.

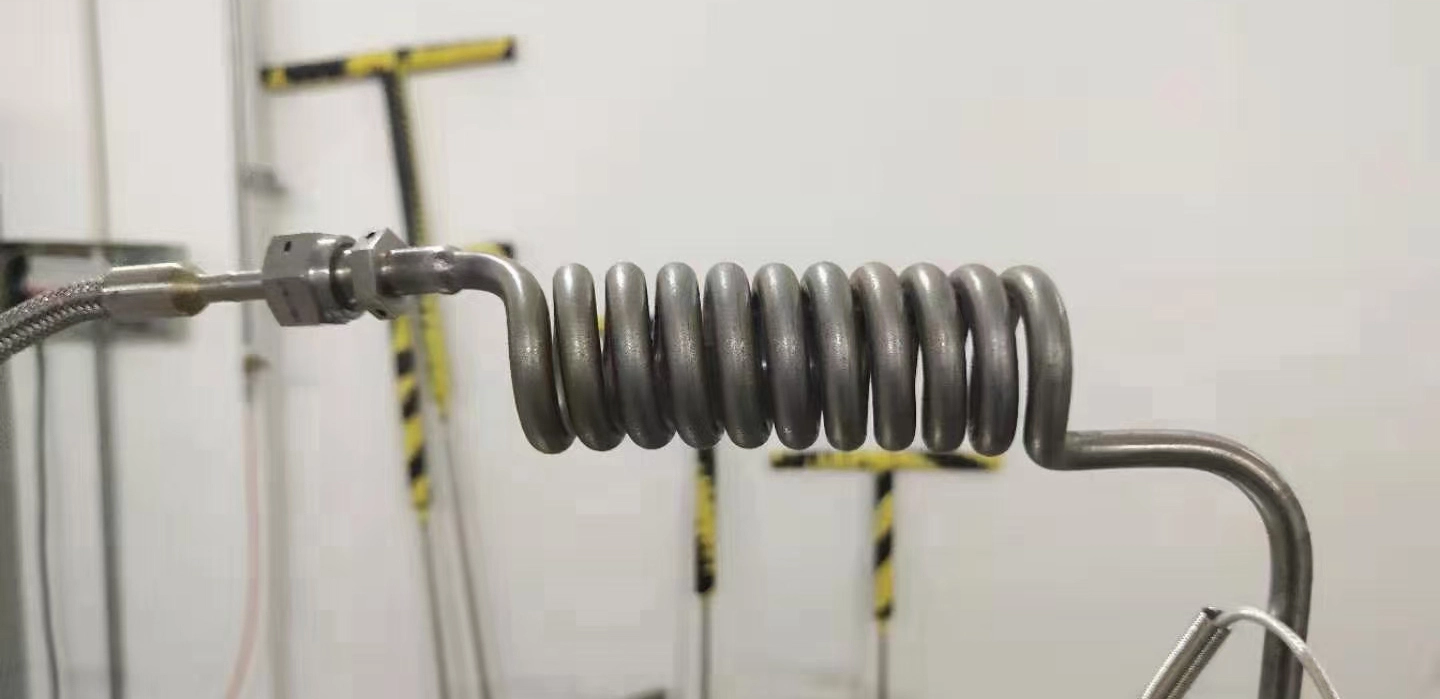

Seamless Tubes: Seamless tubes are thinner and have a smaller diameter compared to pipes, making them lighter and more flexible. They are ideal for applications requiring tight tolerances and intricate bends.Cost:Seamless Pipes: The manufacturing process for seamless pipes involves more complex machinery and longer production times, which can make them slightly more expensive than seamless tubes.

Seamless Tubes: As they have a simpler manufacturing process and smaller sizes, seamless tubes tend to be less expensive compared to seamless pipes.In summary, the main difference between stainless steel seamless pipes and tubes lies in their manufacturing process, intended use, strength, and cost. Pipes are used for fluid transportation and are stronger, while tubes are used in precision applications and offer flexibility.

The German Hydrogen Embrittlement Report is a research report on the development of hydrogen energy in Germany. The report makes a comprehensive analysis of the current situation, development trends, and policy environment of the German hydrogen energy industry, and puts forward relevant recommendations.

The German Hydrogen embrittance report first introduced the importance and potential of hydrogen energy, pointing out that hydrogen energy as a clean energy can play an important role in reducing carbon emissions and achieving energy transformation. The report then analyzes the current situation of the German hydrogen industry, including market size, technology level and competitive situation. The report pointed out that although Germany has strong strength in hydrogen technology research and development, there are still challenges in commercial application, and the market size is relatively small.

Next, the report explores the opportunities and challenges for hydrogen development in Germany. The opportunities mainly include the promotion of government support policies, the strengthening of international cooperation, and the development of emerging technologies. However, challenges include high costs, technical difficulties and lack of relevant infrastructure.

Finally, the report gives a series of recommendations to promote the development of the German hydrogen industry. The recommendations include developing more incentive policies, supporting research and innovation, strengthening international cooperation, and upgrading hydrogen energy infrastructure. In summary, the German Hydrogen Embrittlement report provides an in-depth analysis of the current situation and future development of the German hydrogen industry, and puts forward relevant recommendations aimed at promoting the healthy development of the German hydrogen industry.

Customer Satisfaction Is Our Honor. Feel free to enquiry us any questions of pipeline materials.